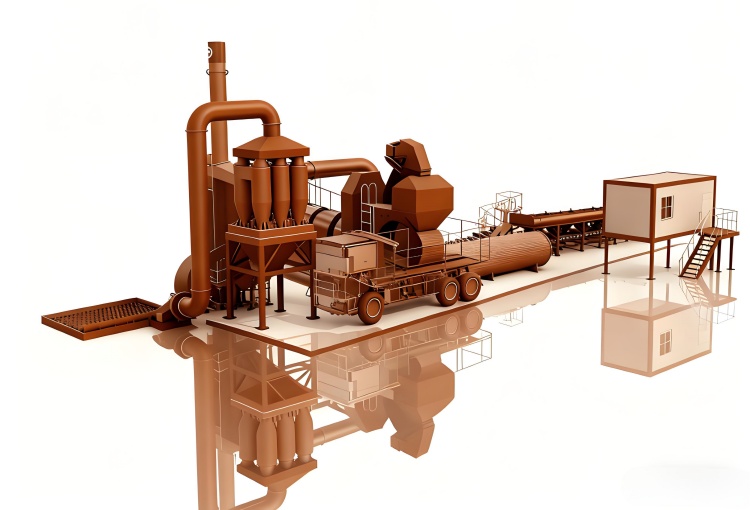

Plant Layout & Configuration

The layout of the asphalt mixing plant can be customized according to site size and project requirements, with modular design options allowing flexible arrangement of cold feeders, drying drum, mixing tower, and bitumen tanks in either linear or parallel configurations to optimize efficiency and workflow.

Capacity Range

Production capacity can be tailored from 60 to 400 tons per hour, with adjustable mixer size and drying drum dimensions to match specific production demands for small, medium, or large-scale projects.

Bitumen System Customization

The bitumen system can be designed with horizontal or vertical tanks, various heating methods such as thermal oil, electric, or direct fire, and customizable tank quantity and capacity to suit different production and storage needs.

Dust Collection & Environmental System

The plant can be equipped with single or multi-stage dust collection systems such as bag filters or cyclone separators, with optional secondary dust removal and noise control features to meet international environmental and emission standards.

Control System & Automation

A fully automated PLC control system with touch-screen operation and optional remote monitoring can be provided, featuring customizable software in multiple languages to ensure easy operation and precise control.

Mobility & Installation Design

Customers can choose between mobile or stationary configurations, with modular structures designed for quick installation, easy relocation, and even foundation-free setup for temporary or frequently moving projects.

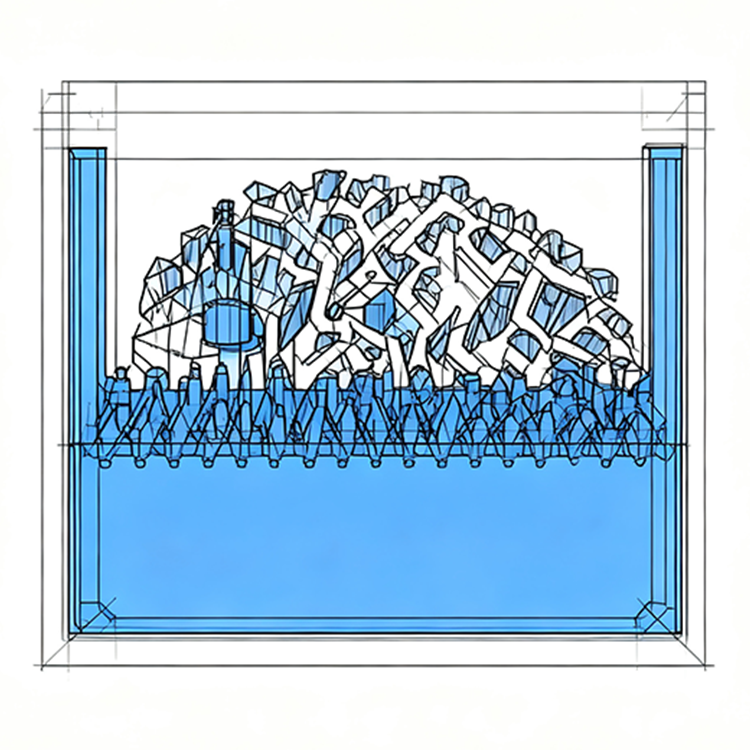

Fuel System Options

The burner system can be configured to operate with diesel, heavy oil, natural gas, or coal, offering energy-efficient and environmentally friendly solutions with low fuel consumption and stable combustion performance.