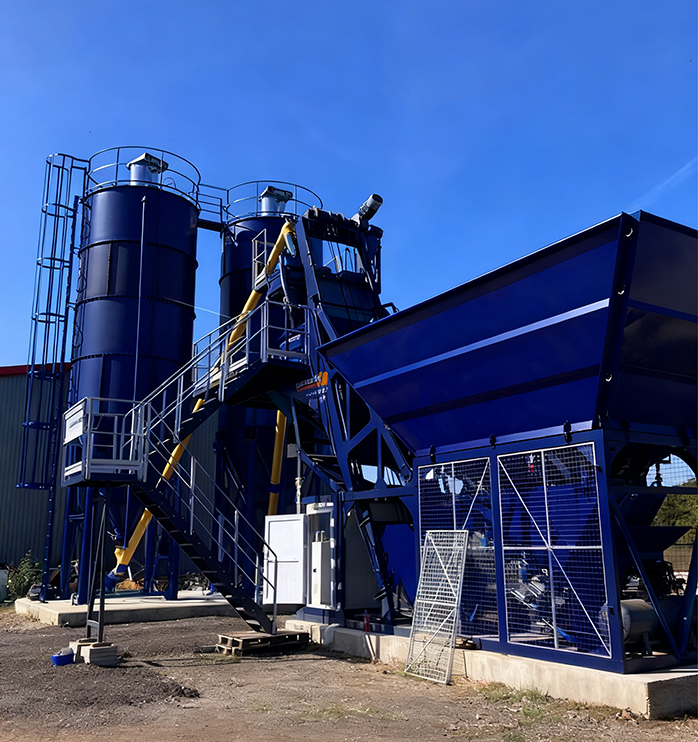

The global construction industry is evolving rapidly, and concrete batching plants are at the heart of infrastructure development. With the increasing demand for faster, more sustainable, and cost-effective construction solutions, investing in high-efficiency concrete mixing plants has become a strategic priority. This article explores how leveraging modern stationary concrete batching plants, mobile concrete batching plants, and dry concrete batching plants can maximize ROI while meeting environmental and operational benchmarks.

1. Understanding ROI in Concrete Plant Investment

Return on Investment (ROI) in concrete production is no longer just about raw output; it encompasses energy efficiency, labor optimization, maintenance reduction, and sustainability. In fact, high-efficiency precast concrete batching plants and volumetric concrete batching plants can reduce energy consumption by 20–35% while minimizing material waste.

Investors should consider the following factors:

-

Initial investment vs. lifecycle cost: High-efficiency plants may require higher upfront capital but reduce operational expenses significantly.

-

Operational efficiency: Automated concrete batching plant control panels and advanced software ensure precise mix proportions and reduce human error.

-

Maintenance optimization: Predictive maintenance extends equipment lifespan and reduces unexpected downtime.

2. Key Features of High-Efficiency Concrete Batching Plants

Modern high-efficiency plants integrate multiple advanced technologies to improve ROI and performance.

2.1 Energy-Efficient Mixing Systems

Concrete mixing plants now employ optimized mixer designs, inverter-controlled motors, and automated batching sequences to minimize energy consumption. Concrete batching plant types such as twin-shaft mixers achieve faster mixing cycles with reduced power draw, allowing plants to handle high-volume projects efficiently.

2.2 Automated Control and Software Integration

Concrete batch plant software and smart control panels enable operators to monitor mix consistency, batch size, and energy usage in real time. These systems reduce human error, improve consistency, and allow for remote monitoring across multiple sites.

2.3 Modular and Mobile Designs

Mobile concrete batching plants and modular precast concrete batching plants provide flexibility for projects with multiple sites. They minimize transportation costs, setup time, and downtime between projects.

2.4 Waste Reduction Technologies

Modern plants incorporate water recycling, aggregate reclaimers, and dust collection systems. Dry mix mortar plants and dry concrete batching plants are particularly effective at minimizing raw material wastage and reducing environmental impact.

3. Technical and Operational Challenges

Investing in high-efficiency plants requires careful consideration of operational and technical factors.

3.1 Calibration and Accuracy

Incorrect calibration of concrete batching plant parts or scales can result in inconsistent mixes, material waste, and increased operational costs. Regular calibration of mixers, scales, and conveyors is critical.

3.2 Integration Complexity

Introducing concrete batching plant software and automated control systems can be challenging, particularly for teams accustomed to manual operations. Training and phased integration are essential to ensure ROI is realized.

3.3 Environmental Compliance

Global markets are enforcing stricter environmental regulations, including carbon emission limits and water conservation mandates. Concrete batching plant manufacturers now offer plants designed to meet ISO 14001 and CE standards, incorporating energy-efficient motors, dust collection, and water recycling systems.

Interestingly, plants designed with volumetric batching systems allow precise on-demand mixing, further minimizing waste and environmental impact.

4. Financial Analysis: Maximizing ROI

To quantify ROI, investors must consider the balance of capital expenditure (CAPEX) and operational expenditure (OPEX).

4.1 Initial Investment

High-efficiency stationary concrete batching plants may cost 15–25% more upfront than traditional systems. Mobile or modular plants may have similar or slightly higher CAPEX but provide greater flexibility and lower setup costs across multiple sites.

4.2 Operational Cost Savings

-

Energy efficiency: 20–35% reduction in electricity usage.

-

Material efficiency: 10–20% reduction in cement and aggregate waste.

-

Maintenance: Predictive maintenance reduces downtime by 15–30%.

4.3 Payback Period

Considering energy savings, material efficiency, and reduced downtime, the payback period for high-efficiency ready mix concrete plants typically ranges from 2–4 years, depending on production scale.

5. Strategic Planning for Plant Investment

5.1 Site Assessment and Layout Planning

A well-planned concrete batching plant layout ensures optimal workflow and minimizes material handling costs. Advanced layout drawings and PDF-based schematics help engineers visualize equipment placement, conveyor systems, and aggregate storage for maximum efficiency.

5.2 Modular Expansion for Growth

Investors should consider modular plant designs that can scale with project demand. This allows integration of additional mixers, silos, or mobile units without significant downtime.

5.3 Supplier Selection

Choosing reputable concrete batching plant manufacturers ensures quality components, compliance with standards, and availability of spare parts. Many companies are sourcing from concrete batching plant manufacturers in China, known for cost-effective, high-quality solutions.

6. Emerging Technologies Enhancing ROI

6.1 IoT and Smart Sensors

IoT-enabled concrete mixing plants provide real-time monitoring of energy consumption, aggregate stock levels, and mixer performance. Alerts for deviations in mix ratios or equipment status prevent costly mistakes.

6.2 Predictive Maintenance

By analyzing historical data from concrete batching plant parts, predictive maintenance schedules minimize downtime and extend equipment life.

6.3 AI and Data Analytics

Artificial intelligence optimizes batch sequences, forecasts material requirements, and improves project scheduling, further enhancing ROI.

7. Global Trends and Market Insights

7.1 North America

High demand for ready mix concrete plants near urban centers is driving the adoption of mobile concrete batching plants, which reduce transportation costs and setup time.

7.2 Europe

Environmental regulations are pushing investments in green concrete batching plants with advanced dust and water management systems.

7.3 Asia-Pacific

Rapid infrastructure growth fuels the deployment of precast concrete batching plants and modular dry concrete batching plants, balancing speed, quality, and sustainability.

8. Cost-Benefit Analysis: Case Studies

Case Study 1: Stationary Concrete Plant Upgrade

A European contractor upgraded a 50 m³/h stationary concrete batching plant with automated controls and energy-efficient motors. Operational costs dropped by 22%, and downtime decreased by 18%, resulting in a projected ROI of 3 years.

Case Study 2: Mobile Concrete Batching Plant Deployment

A Southeast Asian infrastructure company invested in a mobile concrete batching plant to service multiple construction sites. Material efficiency improved by 15%, transport costs fell by 25%, and overall ROI increased by 30% over four years.

9. Long-Term ROI Strategies

-

Training & workforce development: Skilled operators optimize production and minimize waste.

-

Lifecycle cost monitoring: Continuous tracking of concrete batching plant cost, maintenance, and energy usage ensures informed investment decisions.

-

Sustainable practices: Incorporating recycled aggregates and fly ash reduces material cost and carbon footprint.

-

Technology adoption roadmap: Gradual integration of smart concrete batch plant software and predictive maintenance ensures continuous efficiency improvement.

10. Conclusion: Strategic Investment in High-Efficiency Plants

Investing in high-efficiency concrete batching plants is no longer optional—it is critical for maximizing ROI in global construction markets. By combining automation, sustainability, and operational optimization, companies can reduce costs, improve quality, and meet regulatory requirements.

For contractors, project managers, and investors, the key takeaway is clear: prioritizing stationary, mobile, and modular concrete batching plants with advanced control systems not only ensures compliance but also delivers measurable financial benefits.