Are You Facing These Problems?

- Are asphalt mixing plant suppliers always charging more than your budget?

- Are the design drawings and production cycle of asphalt mixing plants too long?

- The construction site limited the layout of the asphalt plant.

- Worried about after-sales service and parts supply?

- Asphalt stations require extremely small errors and very high precision.

- Do you want everything to be customized to your specifications?

- Want to obtain product certification and test reports in advance?

- The project has a short timeframe and requires rapid production and deployment.

- We hope the equipment is simple to operate and supervise, and that personnel training is readily available.

- Are you worried that the other party is not a factory, but a trading company?etc.

SDCAD is a Chinese manufacturer and supplier of asphalt mixing plants with 31 years of experience. With service centers in multiple countries and regions, we are capable of meeting the global demand for high-quality asphalt plants (capacity: 20-400 cubic meters/hour) at reasonable prices. Our fundamental commitment is that the price and quality of our asphalt plants will absolutely meet your expectations. Let’s get started on addressing your needs.

- Time: December 14, 2025

- Location: Cambodia

- Equipment : LB-S160 Asphalt Mixing Plant

- Burner: Coal-oil dual use burner

- Motor: 380V /50HZ

- Results & Value Delivered:

1. 30% higher production efficiency with fast commissioning.

2. Consistent, high-quality mixes that meet all standards.

3. Simple operation with significant labor savings.

- Date: January 2023

- Country: Kenya

- YLB-M120 Mobile Asphalt Mixing Plant

- Capacity: 120TPH

- Voltage and frequency: 380V/50HZ

- Results & Value Delivered:

1. Optimized design reduced equipment costs by 21%.

2. Overseas engineers traveled to the location, completing installation two weeks ahead of schedule.

3. Modular design reduced shipping costs by 30%.

Types Of Asphalt Mixing Plants

SDCAD, as a professional manufacturer of Asphalt Plant, Stationary Asphalt Mixing Plant , Mobile Asphalt Mixing Plant, Drum Asphalt Plant, Simple type Asphalt Plant (capacity range from 20-400 tons/hour), can meet all requirements of construction projects.If you are looking for a cost-effective asphalt mixing plant for sale,we will provide you with a satisfactory asphalt mixing plant price.

Stationary Asphalt Mixing Plant33

Stationary Asphalt Mixing Plant33 Mobile Asphalt Mixing Plant33

Mobile Asphalt Mixing Plant33 T-type Mobile Batch Mix Plant33

T-type Mobile Batch Mix Plant33 Super Mobile Batch Mix Plant33

Super Mobile Batch Mix Plant33 Super Mobile Drum Mix Plant33

Super Mobile Drum Mix Plant33 Continuous Asphalt Mixing Plant33

Continuous Asphalt Mixing Plant33 Eco-friendly Asphalt Mixing Plant33

Eco-friendly Asphalt Mixing Plant33

Stationary Asphalt Mixing Plant

- Capacity: 40~400t/h

- Mixer Capacity: 500-5000kg

- Drying Drum Size: (1200~3600)*(5200~10800)mm

- Fuel Consumption (oil): 6.5-7kg/t

- Advantages & Features

-

High ProductionMost popular for high output and high cost performance, maximum output can reach 400tph.

-

High EfficiencyDiesel, heavy oil, natural gas, coal or multi-fuel burners for choose, save cost for client’s project.

-

Energy Saving&ECO-friendlyLow maintenance operation&energy consumption&emission. Optional environmental design to customers need.

-

Easy to Install and MaintainRational layout, simple foundation, easy to be installed and maintenance. Energy saving, safe and easy to operate.

Get Your Custom Quote

Mobile Asphalt Mixing Plant

- Capacity: 60~320t/h

- Mixer Capacity: 800-4000kg

- Drying Drum Size: (1500~2600)*(6000~9000)mm

- Fuel Consumption (oil): 6-7kg/t

- Advantages & Features

- Easy Installation & Mobility

Modular design is convenient and fast to move and install, saving time and cost of installation. -

Simplified Transport & AssemblyLess transport vehicles and installations requires no tradition foundation works, easily transportable and assembling.

-

Compact & Efficient OperationCompact structure, occupied area is smaller. Low maintenance operation & energy consumption & emission.

-

High-Quality Mixture AssuranceAccurate screening, accurate weighing and batch forced mixing, make sure that asphalt mixture is high quality.

Get Your Custom Quote

T-type Mobile Batch Mix Plant

- Capacity: 60~200t/h

- Mixer Capacity: 800~2500kg

- Fuel Consumption (oil): ≤6.5kg/T

- Total Power: 154~500kW

- Advantages & Features

-

High-mobility, Compact DesignAdopt Korea DMI structure design, high mobility performance, small land occupied, convenient transportation and little downtime.

-

Easy-connect Aviation PlugsAdopt AVIC brand Aviation Plugs, easy connection, fast disassembly and assembly wires.

-

Simple, Reliable ControlSimple and convenient production technology process, accurate, highly reliable and stable control system

-

Fully Automatic ProcessesSystem of drying, weighing, mixing, discharging are full-automatically controlled.

Get Your Custom Quote

Super Mobile Batch Mix Plant

- Capacity: 40-90t/h

- No. of Aggregate Bins: 2-4

- Movement: Semi-trailer, fully mobile

- Dust Collector: bag-type dust /water dust removal

- Advantages & Features

-

Fast Relocation and TransferNo need for secondary assembly at the construction site. All cables are installed and debugged before leaving the factory, and only cable connections between the frames are needed during each transition.

-

High IntegrationCold aggregate, drying, screening, measuring, mixing and all other main equipment can be integrated on one chassis.

-

Semi-trailer Design, Standard Tractor TowingSuitable for international standard 50# and 90# trailer couplings. It meets various traction interface requirements such as 4×4 and 6×4.

-

Customized DesignMultiple configuration combinations are available to meet different construction needs. The number of aggregate silos, dust removal methods, fuel types, etc. can be selected and customized.

Get Your Custom Quote

Super Mobile Drum Mix Plant

- Capacity: 20~200t/h

- Fuel Consumption (oil): ≦7kg/t

- Drying Drum Size: (1200~3800)*(1800~8500)mm

- Filter Area: 115-340m²

- Advantages & Features

-

Compact & Efficient InstallationThe drum mix asphalt plant with compact type, could meets the user’s requirements for fast installation, fast transition, and rapid production.

-

Highly Integrated FunctionalityRealizes the high integration, just one transport trailer can realize all the functional requirements (filling, drying, mixing, storage, operation).

-

Cost-Saving ConvenienceThe convenience of fast transportation, no foundation required and rapid recommissioning greatly saves costs and improves construction efficiency.

-

Versatile Application ScenariosSuper mobile drum mix asphalt plant widely used in the road construction that can be portable or stationary.

Get Your Custom Quote

Continuous Asphalt Mixing Plant

- Capacity: 20~200t/h

- Fuel Consumption (oil): 5.5-7kg/t

- Drying Drum Size: (1000~4500)*(1950~9000)mm

- Operation Method: Manual/Semi-automatic

- Advantages & Features

-

User-Friendly & Cost-Effective DesignSimple structure, easy to move and maintain, and with low equipment investment. Can be equipped with RAP and filler system

-

Efficient Heating & Fuel-SavingConcurrent type drying drum structure, efficiency of heating aggregate is higher than downstream type, lower fuel consumption.

-

High-Quality Mixing PerformanceSeparated continuous type mixer, the mixing performance is high and make sure the quality of asphalt mixture.

-

Smooth Conveying & Low MaintenanceScraper type elevator take the asphalt mixture cleaning and smoothly. Maintenance-free parts could reduces procurement and repair costs.

Get Your Custom Quote

Eco-friendly Asphalt Mixing Plant

- Capacity: 80~400t/h

- Mixer Capacity: 1000~5000kg

- Bitumen Aggregate Ratio: 3%-9%

- Mineral Powder Proportion: 4%-12%

- Advantages & Features

-

Efficient Two-Stage Dust RemovalThe dust removal system adopts a rotary back flushing dust collector, two-stage dust removal and off-line cleaning. Efficient dust removal system.

-

Sealed Aggregate StorageThe aggregate is stored by sealing and the material yard is enclosed fully to prevent the dust from flowing outwards, reduce the additional energy consumption in drying the aggregate.

-

Enclosed Batching Station (Dust Control)The three-side all-package of the batching station, increased by the controllable negative pressure encapsulation, and the suction belt is added at the feeding belt to solve the dusting problem of the belt conveyor.

-

Self-Developed Waste Powder ProcessorUse the Self-research and development’s waste powder processor, can control the amount of recycled powder, accurately control the water-cement ratio, and recover after humidification.

Get Your Custom Quote

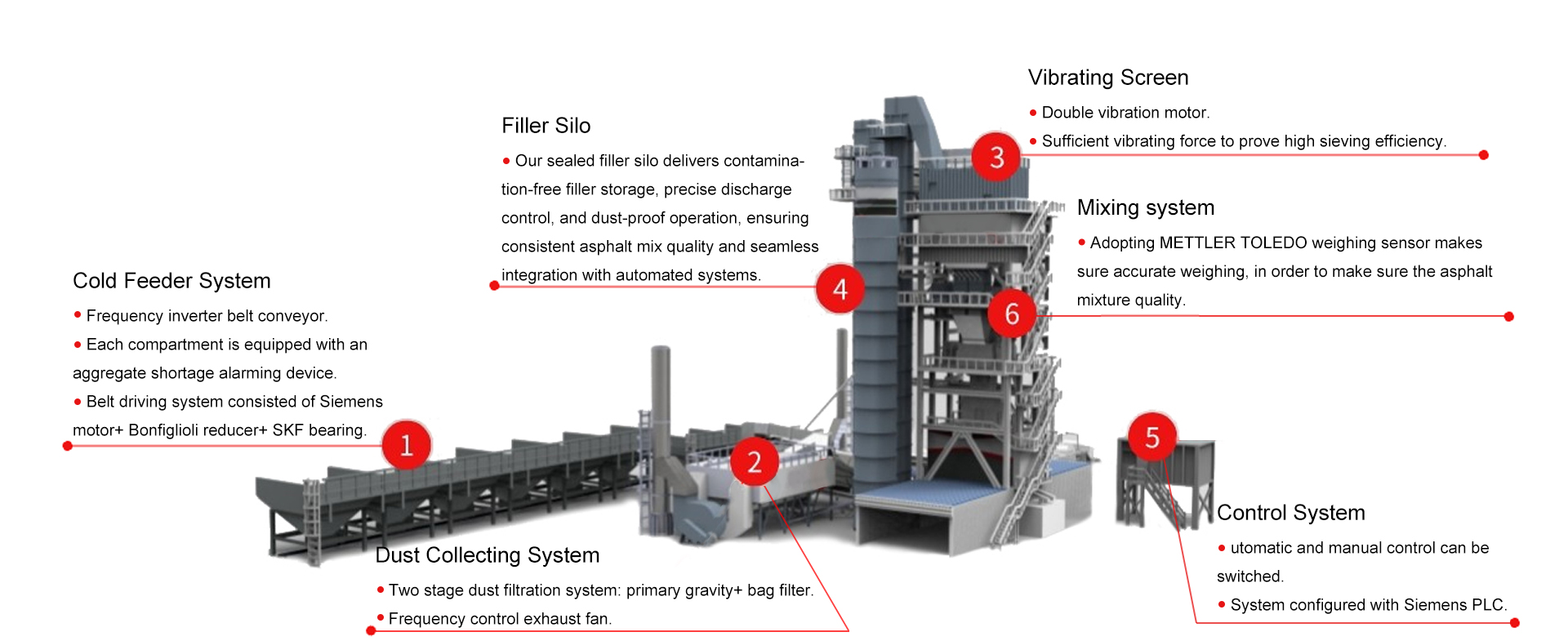

Asphalt Mixing Plant Main System

Recent Visiting Customers

Recent Visiting Customers

With 31 years of production experience and technological advancements, we can undertake the design and production of all types of asphalt mixing plants.

Recent Visiting Customers

We ensure that while reducing the cost of asphalt mixing plants, we guarantee the high quality of our equipment.

Recent Visiting Customers

We hope you will visit our factory and begin our further cooperation.

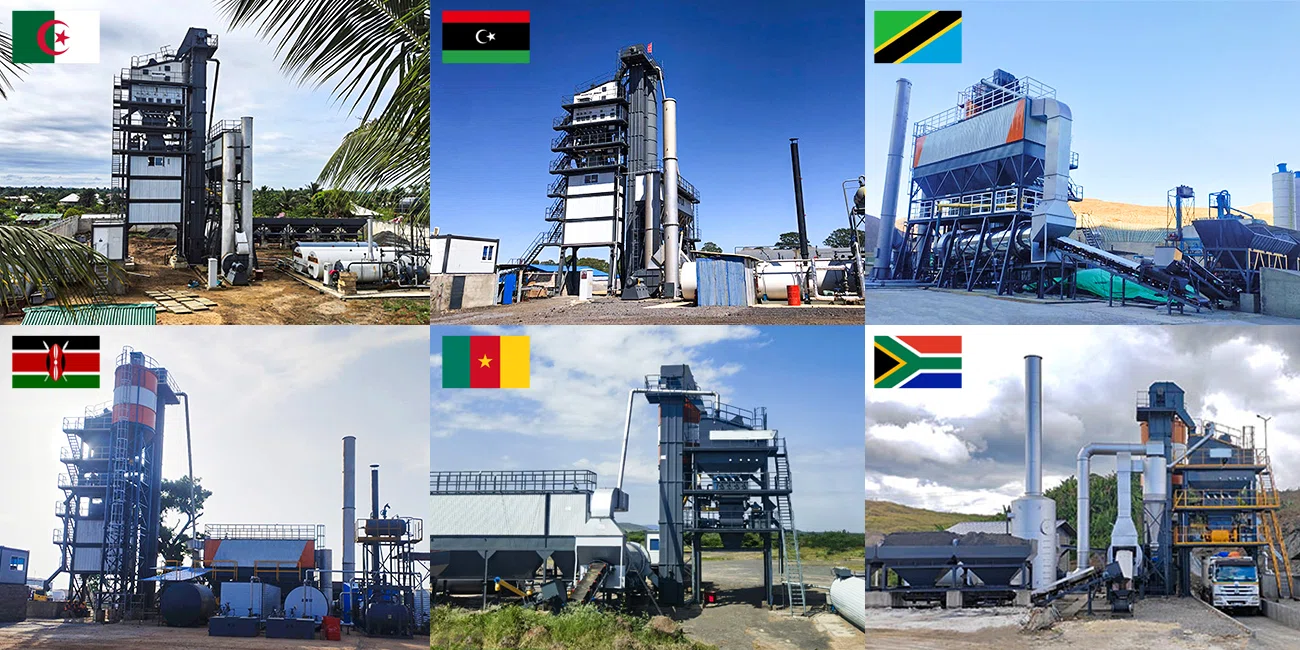

Recent Project Showcase

We have successfully exported multiple asphalt mixing plants to 103 countries and regions worldwide, supporting infrastructure and road construction projects across various countries and regions. From major highways to local road maintenance, our asphalt mixing plants play a vital role in the development of our partners’ construction industries. With our local support and service teams, we ensure smooth equipment installation and ongoing maintenance, making us a trusted partner in the global asphalt production industry.

- Country: Republic of Congo

- Time to production: September – October 2024

- Product: 60 t/h mobile asphalt batch mixing plant

- Model: YLB-M60

- Voltage: 380V/50Hz

- Color: Sky blue

- In September 2024, our company sent two professional engineers to Congo to assist customers in installing and commissioning a 60TPH mobile asphalt plant. After nearly 40 days of intensive struggle, the installation and commissioning of this asphalt station was successfully completed.

- Time: May 25, 2025

- Location: Uzbekistan

- Equipment: LB-S100, 100T/H Stationary Asphalt Mixing Plant

- As a key participant in the Belt and Road Initiative, Uzbekistan has been continuously increasing its investment in road infrastructure construction and upgrading. To further expand its business and seize this opportunity, our client visited our asphalt mixing plant in Uzbekistan and highly praised the quality of our products. Ultimately, they purchased a 100-ton/hour intermittent asphalt mixing plant from our company.

- Date: March 16, 2024

- Location: Kano, Nigeria

- Equipment: YLB-M80 80 tons/hour mobile asphalt mixing plant

- SDCAD’s first mobile intermittent asphalt mixing plant in Nigeria was installed and commissioned on March 16. After 25 days of hard work, the mobile asphalt mixing plant has been successfully put into operation.Nigeria has always been an important market for us. SDCAD has exported seven asphalt mixing plants to Nigeria, including six stationary asphalt mixing plants and one mobile asphalt mixing plant.

- Time: March 10th, 2025- April 15th, 2025

- Location: Osh, Kyrgyzstan

- Model and output: LB-S60, 60T/H

- This asphalt mixing plant consists of a 4pcs bin cold material system, a drying drum, a coal-fired burner, a combined cyclone dust removal and water dust removal system, a mixing tower system, a pneumatic system, an electric bitumen heating system, and a fully automatic computer control system. In order to ensure the stability of the control system, electrical components are all imported brands such as Siemens.

Services provided by SDCAD in global sales

SDCAD boasts a professional sales team and overseas warehouses, enabling us to provide customers with superior and faster service. As a leading asphalt mixing plant manufacturer in China, we offer the most competitive prices for asphalt mixing plants price. We welcome customers from all over the world to visit our multiple factories and offices.

CONTACT US

If you have any questions, feedback, suggestions, or other assistance, please fill out the form below.

We need to know several things:

1. List the specific equipment or its type (e.g., asphalt mixing plant, batching plant, self-loading mixer, concrete pump, crushing plant, etc.).

2. Output capacity (m3, tons/hour)? Product model?

3. Project start time? Project duration?

4. Is it a tender project or an in-house project?

5. Project type (e.g., building a house, factory, road, bridge, dam, airport, etc.).