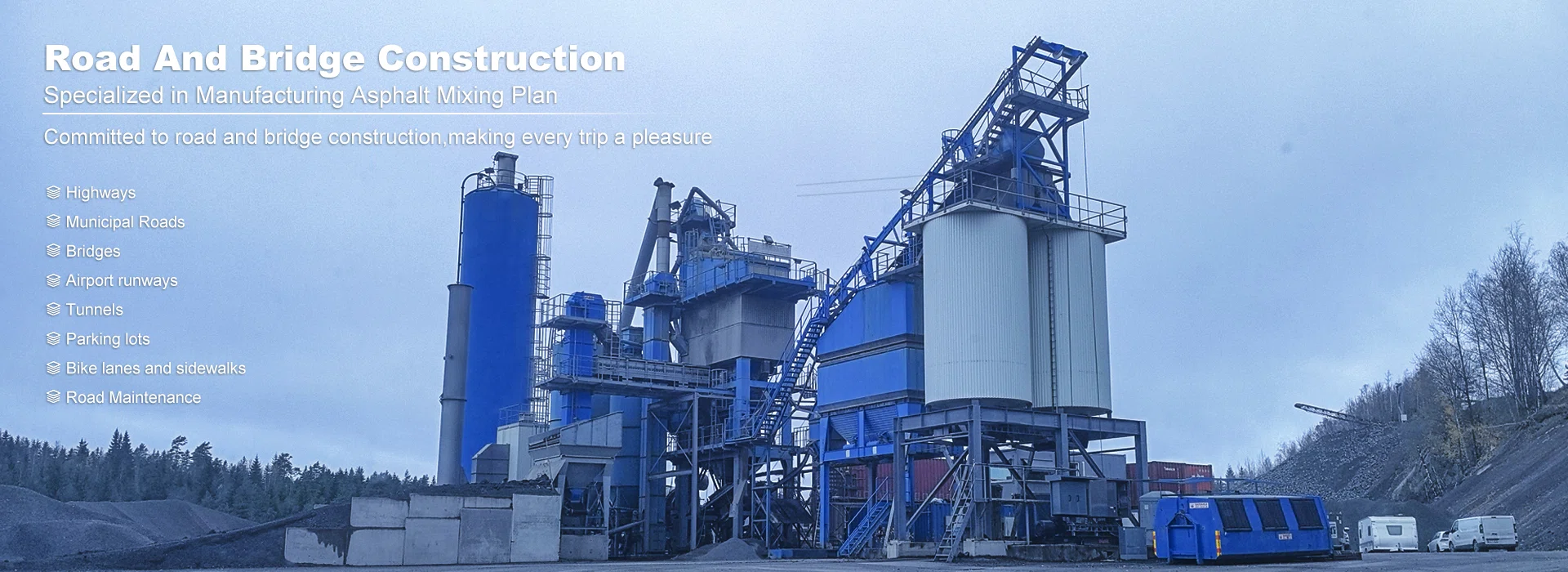

Asphalt Plant for Sale – Factory Direct Price & Global Delivery

Looking for a reliable asphalt plant for sale to power your next large project? If you’re facing budget overruns, lengthy design cycles, and uncertainty about which option to choose and so on, SDCAD offers customized, cutting-edge asphalt mixing solutions – efficient, durable, and capable of producing high-quality asphalt.

Different types of Asphalt Plant For Sale

So, which type of asphalt mixing plant is right for your project? Understanding the different types of concrete mixing plants is crucial, considering factors such as application scenario, construction environment, production capacity, and more. SDCAD offers stationary asphalt mixing plants, mobile asphalt mixing plants, and drum asphalt plants. Let’s learn about these products to choose the most suitable asphalt plant.

Stationary Asphalt Plant for sale

- Capacity: 80 t/h ~ 400 t/h

- Mixer Capacity: 500kg/batch ~ 5000kg/batch

- Highlights: Batch mix, batch mix, precise aggregate batching and weighing; Classic model, wide application, highly cost-effective, best-selling.

-

Key Benefits

- High Output: Ideal for projects like highways and airports.

- Low Fuel Consumption: 13-15kg/t, ensuring cost-effective operation.

- Durable & Stable: Perfect for long-term use with optimized components for minimal wear.

- Eco-Friendly: Equipped with a bag dust filter, capturing up to 95% of dust emissions.

- Efficient Operation: Optimized for fuel efficiency.

Get A Quote

Mobile Asphalt Plant for sale

- Capacity: 60 t/h ~ 160 t/h

- Mixer Capacity: 700kg/batch ~ 2000kg/batch

- Highlights: Batch mix, precise screening, accurate weighing, high quality output; easy for installation, fast relocation.

-

Key Benefits

- High Mobility: Quick setup and relocation, saving time and reducing site preparation costs.

- Efficient Production: Output providing reliable production for various project sizes.

- Low Operating Costs: Fuel consumption of 5-7.5kg/t (fuel oil) or 13-15kg/t (coal).

- Eco-Friendly: Dust filter captures up to 95% of dust.

- Compact Design: Saves space with a 30% smaller footprint.

Get A Quote

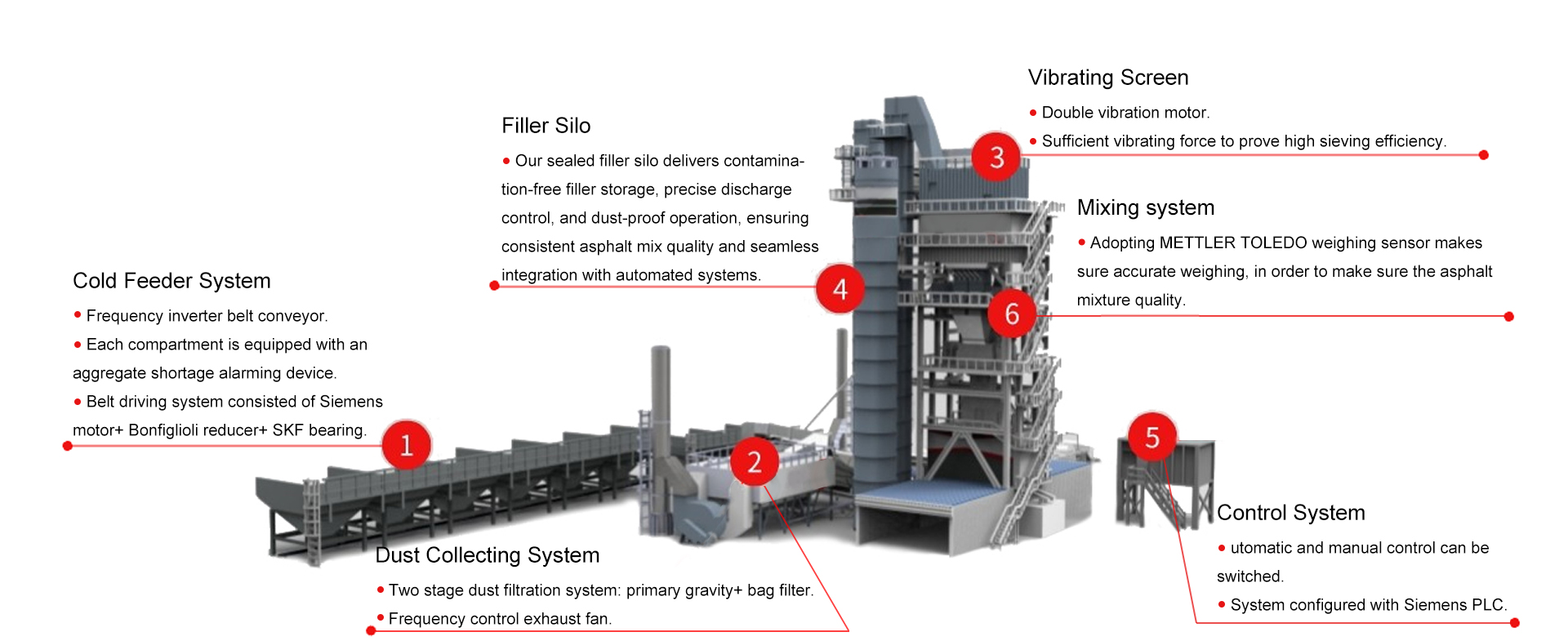

components of asphalt plants currently for sale

Main factors of asphalt plants for sale

Production demand matching: Focus on three key indicators

- Rated production capacity: Determined based on the project’s daily/monthly asphalt mixture demand and construction period.

- Production material type requirements: Clearly define the types of mixtures the project needs to produce.

- Construction scenario adaptation: Differentiate between fixed, mobile, and semi-mobile facilities, while considering site area and transportation conditions.

Core Equipment Configuration and Process Reliability

The core configuration of the equipment directly determines the long-term failure rate, mixture quality accuracy, and equipment lifespan. It is a core hardware indicator for selection, focusing on core components and process design rather than simply brand or price:

- Core Component Configuration: Prioritize core components from established brands for easier maintenance and parts procurement.

- Process Design Rationality: Consider whether the equipment includes a precise temperature control system, environmental dust removal, and automatic additive blending devices.

- Overall Equipment Reliability: Consider the frame material, the integration level of each system, and the manufacturer’s process maturity.

Overall Operating Costs

- Procurement Costs and Cost-Effectiveness

- Operating Energy Costs: Focus on fuel/gas consumption and electricity consumption

- Maintenance and Parts Costs: Lifespan of core components, availability and price of parts, and manufacturer’s after-sales maintenance services.

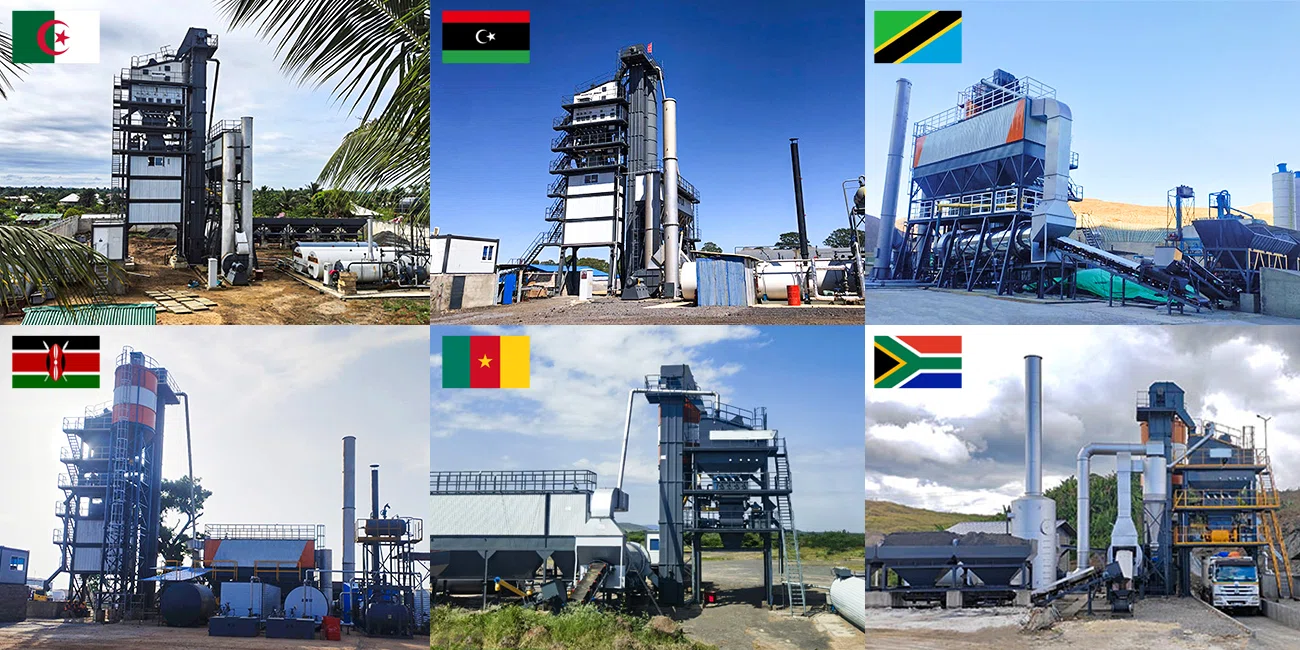

Global Project Cases of Asphalt Plants for Sale

To date, SDCAD has exported to over 100 countries and regions, and has sold over 800 asphalt mixing plants. We welcome you to visit our project sites at any time.

SDCAD’s direct-sales asphalt mixing plants have supported several landmark infrastructure projects in South America, including Brazil’s BR-163 national highway and Colombia’s Bucaramanga-Cúcuta Andes highway project. Two LB-5000 mixing plants supplied high-quality asphalt mixtures for this 3,579-kilometer-long agricultural transportation artery in Brazil, solving the production challenges in high-humidity environments with their low fuel consumption advantage. Mobile asphalt mixing plants also supported the expansion project of the Bogotá-Giradote highway in Colombia, providing a stable supply of over 800,000 tons of asphalt mixtures for the road widening project.

SDCAD’s direct-sale asphalt mixing plants have supported the Buckey Road recycled asphalt overlay project in Phoenix, USA, and the modernization plan for the Federal Highway in Mexico. In Arizona, the equipment produces environmentally friendly hot-mix asphalt with 20% recycled materials for Phoenix’s busy main roads, significantly reducing greenhouse gas emissions and the consumption of virgin materials.

The LB-1500 asphalt mixing plant, sold directly from manufacturers, has served the upgrade project of the Kananga-Kasingi section of National Highway 1 in the Democratic Republic of Congo and a key highway project in Cameroon. This equipment has increased production capacity by 10%-15% for this core transportation artery in the DRC. Its modular and rapid installation saves 5-10 days of construction time, and it maintains stable output even in harsh construction environments. Simultaneously, it provides supporting equipment for the Kribi Port asphalt supply chain project in Cameroon, helping to reduce local highway construction costs by 30%.

CONTACT US