What Are the Core Components of an Asphalt Plant?

Aggregate Batching System: Main Components and Working Principle

The aggregate batching system is the heart and soul of an asphalt plant’s raw material intake. Its primary role is to accurately store, transport, and weigh various types of aggregate prior to mixing. This preparation conditions each batch created in the plant, so its output must be consistent and accurate.

The following bullet points list the key parts found in most batching setups:

-

Aggregate storage bins for graded raw material

-

Vibrating feeders to move and control flow

-

Conveyor belts that carry aggregates to the weighing system

-

Pneumatic valves for directing aggregates to correct silos

-

Dynamic weighing hoppers, fitted with high-precision load cells

-

Aggregate moisture content sensors for real-time adjustment

The batching system’s working principle rests on the requirement for close oversight of every batch’s mix ratio. Aggregates are stored in different bins with each bin holding a specific size range, usually 0-3mm, 3-5mm, 5-10mm, and 10-15mm. These bins keep raw materials segregated and on hand.

Upon start-up, vibrating feeders open to spill each aggregate size onto conveyors. The amplitude of these feeders is important because if it’s not enough, then the flow jams and blockages occur at the outlet of the bin. Too much and the material might surge, which can skew weighing accuracy.

The conveyor belts deliver the chosen material to the dynamic weighing hopper. This hopper houses a load cell accurate to ±0.5%, critical because any batch that is off by more than 0.5% in asphalt content can cause pavement to crack or loosen. When the precise weight for each size is attained, the pneumatic valves open and aggregates fall into hot aggregate silos. This stream guarantees that every batch meets the design mix, enabling steady plant production.

Moisture content sensors are central to keeping the mix right. They read the moisture in each aggregate type in real time, aiding in the modification of dry material quantity. If aggregates contain additional moisture, it reduces the quantity weighed, so the finished batch contains the dry weight desired.

This crucial intermediate step is important for plants in climates where weather is variable or aggregate piles collect rain. Without this check, the mix can be too wet or too dry, resulting in bad pavement.

The batching system influences the entire plant’s throughput and dependability. By stockpiling cold aggregate in graded stockpiles and monitoring for clumping or low stock, operators ensure a steady feed.

The aggregate batching system operates with drying, heating, screening and mixing. If something like a blocked feeder or a missed grade slips, the entire line bogs or halts. When each phase flows, growers can achieve a higher daily yield, maintain denser quality, and scrap less product.

Mixing System: Main Components and Working Principle

Mixing system: This is where the bulk of the work gets done in an asphalt plant. It combines ingredients and transforms them into a workable asphalt blend. The principal components are the mixer, drying drum, burner, and aggregate feeder. Each component has a special role in the formula, and all of them determine the outcome.

Of course, at the heart lies the mixing drum and mixer. In batch type plants, the mixer consists of two arms and tips on shafts. These components rotate and agitate, ensuring that all the lumps, binder, and filler mix thoroughly. This portion of the system operates in cycles, allowing each batch equal mixing time.

Batch mixing has a batch gap because of its stop-start cadence. This provides greater control over every mix and diminishes the speed. Continuous type plants don’t pause either; they run one mix recipe at a time, chugging the materials through the system in an uninterrupted flow. This variety is good for large-scale jobs, but the recipe can only be altered when the run ends.

The drying drum is another crucial component. It’s divided into two parts. The first part uses a burner to heat the raw aggregates. This is a must because wet or cold aggregates will not blend with bitumen. The second half of the drum is responsible for the mixing.

This is where the hot aggregates are introduced to bitumen and filler. The objective is to achieve homogenous, uniform blending that can withstand pressure. If the heat is off or the mix is uneven, the finished product won’t stick around.

Advanced control panels are increasingly common in contemporary plants. They allow operators to observe and adjust the mix in real time. In other words, it is simpler to maintain a consistent temperature, correct mix ratio, and accurate batch size.

Armed with additional sensors and smarter software, modern control panels reduce waste and increase throughput. If the system must switch between mix recipes or adjust to variations in raw material quality, this is particularly important.

Blend control is major QC. The system has to be capable of using various types of aggregates and bitumen, which can vary from job to job. Aggregate feeders must dose the correct quantity of stone, sand, and filler in each batch.

Bitumen tanks need to maintain the feed hot and stable. Aggregates and bitumen account for more than 75% of the cost, so prudent control prevents loss. Fuel for the burner contributes an additional 12% to the cost, thus using the optimal quantity is important.

Well-designed plants can change production rates, change materials, and maintain quality even as the job specs change.

Asphalt Supply System: Main Components and Working Principle

The asphalt supply system is at the core of any contemporary asphalt plant. Its core function is to transport, heat, mix, and provide a continuous supply of quality hot mix asphalt. It is essential for each component to operate in synchrony for an asphalt plant to run smoothly, deliver under strict specifications, and meet demand.

A solid understanding of the individual components and how they function collectively aids operators, engineers, and planners in making informed decisions, minimizing waste, and maximizing efficiency.

Key parts of the asphalt supply system include:

-

Aggregates feeding system

-

Drying and mixing drum

-

Asphalt storage tank

-

Liquid asphalt metering unit

-

Control system

-

Dust removal system

-

Storage silos for finished mix

Aggregates, which constitute the majority of the mix, are stored and fed into the system through a feeder system. The drying and mixing drum is where the magic happens. It spins at a consistent 3 to 5 rpm, heating the aggregates and combining them with liquid asphalt.

This drum must be maintained at a specific temperature and at a constant speed to ensure a uniform mix. The mixing process only takes approximately 20 minutes so that each stone, filler, and additive can mix thoroughly with the asphalt.

The asphalt storage tank has an important role. It maintains the asphalt at the correct temperature, typically between 140 and 160 degrees Celsius, through a heating coil and insulation. Maintaining the temperature is key because it drops the asphalt’s kinematic viscosity to approximately 0.1 to 0.3 Pascal seconds.

This means the asphalt streaks nicely and covers every grain of aggregate without lumps and clumps. This step counts no matter if the plant is in a cold spot or a hot one, as consistent heating is a must.

One other important step includes metering the liquid asphalt. The metering unit determines the amount of asphalt delivered to the mix, maintaining the correct ratio time after time. If the quantity is even slightly off, you could have feeble pavement or waste expensive ingredients.

By monitoring flow speed and adjusting in real time, the metering unit helps maintain a consistent mix quality and satisfy project specifications. This is particularly crucial for large-scale works like highways or airport runways where quality can’t falter.

Heating does more than keep things liquid. It paves the way for effective coating and bonding, maintaining the mix workable and preventing it from cooling prematurely. If it falls below or above that range, the mix turns stiff and difficult to spread.

By managing heat in the storage tanks, drum, and silos, the plant maintains the mix optimal for loading and delivery.

The system employs a dust removal system that captures dust over 5 microns. With a combination of inertial collision and centrifugal force, it can capture up to 99.5 percent of these particles. This keeps the air cleaner, reduces waste, and assists the plant in complying with health and safety regulations.

A modern control system integrates it all. It monitors each component in real time, making adjustments as necessary for flow, temperature, and cadence. This keeps the operation efficient and consistent, even as demand or weather fluctuate.

The hot mix asphalt is then stored in insulated silos. These silos maintain the mix hot and fresh, prepared for either truck load-out or direct to pavers, preventing premature cooling and hardening.

Filler Supply System: Main Components and Working Principle

Filler supply system is the unique main unit of an asphalt mixing plant. Its primary function is to provide filler materials such as mineral powder to the mixing site. This step defines not only how the mixture functions but how durable your pavement is.

It is comprised of a filler silo, screw or sometimes pneumatic conveyor, and frequently a dust collector. Every component performs a specific function, and all must operate in concert to maintain a balanced and consistent blend. The silo stores the filler, dry and prepared. When the mixer demands, the screw conveyor or pneumatic line delivers precisely.

Some plants even add a dust collector, which attracts dust from the air, making the work site cleaner and safer for people and the planet.

The system’s core philosophy is control. The filler is kept in a separate bin or silo, separated from the other components of the mix. As the plant operates, the system supplies the filler in a controlled, pulsed stream. This maintains the mixture’s composition consistent from batch to batch.

One small lapse here, too much or too little filler, can alter the entire blend. It can cause the finished pavement to be fragile, rough, or brittle. To ensure this, it incorporates flow meters, weigh sensors, or occasionally manual inspections. In larger plants, these checks are probably digital, with software monitoring every kilo of filler passing through.

Accurate metering is crucial. Just the right amount of filler alters the properties of asphalt. A higher filler rate may cause the mix to become stiff and less prone to flow under load. In excess, it can reduce its stick and water resistance.

If you don’t add sufficient filler, the mix may not stick together or endure as long. For example, stone dust provides mixes with additional grip, whereas hydrated lime can assist the mix in handling water better and extending the aging process. Each type of filler imparts its own effects, and plants can swap or mix fillers to fit what the work demands.

Urban centers with lots of truck traffic could add extra mineral powder for strength, while frigid regions might include fly ash to help the mix survive freeze/thaw cycles.

It matters how the filler supply system and the mixing system work alongside each other. The following table outlines their key interfaces.

|

Filler Supply System Role |

Mixing System Role |

Interaction Outcome |

|---|---|---|

|

Feeds measured filler amount |

Mixes aggregate, binder, filler |

Ensures uniform blend and right composition |

|

Adjusts flow based on demand |

Receives feedback from sensors |

Keeps mix properties within set limits |

|

Collects dust and recycles |

Incorporates recycled filler |

Cuts waste and supports eco-friendly goals |

The configuration of each plant’s filler system is flexible. Smaller plants can utilize a simple screw conveyor, whereas higher-production locations require a complete pneumatic line. The dust collector’s size and power vary too, depending on plant output and local air quality regulations.

No matter the setup, the aim is always the same: keep the mix steady, safe, and up to standard.

Finished Mix Storage System: Main Components and Working Principle

Finished mix storage system is the heart of any asphalt mixing plant. It stores the finished mix before delivery to construction. The key is to maintain the mix freshness until delivery.

Completed Mix Storage System – Key Elements and Operating Principle

The key components are storage bins, silos, conveyors and a control system. Storage bins are frequently cone or rectangular shaped. This allows the asphalt mix to slide out quickly and easily, minimizing delays. Silos are popular, particularly for facilities required to stockpile large amounts of mix. Silos can be isolated or in a series, with each containing various types of asphalt. Nearly all silos and bins have heaters installed. These heaters maintain the mix at the appropriate temperature.

Conveyors transport the mix from mixer to bins or silos. The control system is the brain. It monitors and controls temperature, flow, and the level of the stored mix. Some systems employ sensors and intelligent controls to monitor mix levels, control filling initiation and termination, and ensure the mix remains unstuck.

It’s all about storing the goodness of the mix properly. If the mix cools too quickly or becomes wet from rain or a broken water pipe, it can clump or lose its potency. That can result in feeble roads or extended repair periods. The bins and silos are sealed tight against rain, dust, or wind. Great insulation keeps the heat in, so the mix remains pliable and workable.

The proper delivery system prevents loss and maintains the mix fresh for hours or even days, something essential for large projects or inclement weather. One of the most crucial parts of the system is temperature control. Asphalt mix must remain between 135° and 163° C. If it falls beneath that, it becomes too gnarly to operate. If it becomes too hot, it could decompose and lose its adhesive properties.

Heaters in the bins or silos utilize oil, gas, or electricity to maintain the temperature of the mix. The control system monitors the temperature continuously and activates or deactivates the heaters accordingly. This way, employees can rest assured the mix is always good to go, reducing waste and rework.

Smart storage solutions assist with project meandering and delivery. They allow plants to produce mix in advance, so trucks don’t have to delay. This comes in handy for rush projects or heavy volume. A nice storage system enables plants to operate extended shifts and dispatch shipments on a regular schedule.

That simplifies job scheduling, controls cost and deadlines. This can vary from small bins for localized jobs to large silos capable of storing hundreds of tons for large-scale road projects.

Electrical Control System: Main Components and Working Principle

A robust electrical control system is vital to the safe, steady and smooth operation of an asphalt plant. At the heart of this system are programmable logic controllers (PLCs), sensors, actuators, and main control panels. These parts function together to monitor and control each phase of the asphalt production process.

PLCs run the show by receiving signals from sensors distributed around the plant. These sensors monitor variables such as mix temperature, flow of material, or drum speed. When the PLC receives this information, it issues on/off or speed instructions to actuators that open or close valves, turn motors on or off, or adjust feeder speeds.

The control panel is where operators monitor and adjust the entire process, with displays presenting live plant conditions, alarms, and fault codes. The core idea is simple: sensors spot changes, PLCs think and decide, actuators do the heavy lifting, and panels show what’s going on.

Automation enhances plant performance through a reduction of human error and simplifying monitoring each step. With effective automation, plants operate with less personnel because systems can initiate, halt, or cease entire processes at the push of a button or even a swipe of a remote control.

The control system can detect problems as soon as they occur, such as a motor drawing excessive current or a conveyor belt running slow. This way, little glitches get repaired before they blossom into expensive failures. Automation simplifies operating the plant at the optimal speed and mix, resulting in less waste and more efficient usage of raw materials.

For instance, if the PLC detects that the storage silo is nearing capacity, it can throttle back or halt the mixer before anything spills over. Remote monitoring allows operators to monitor the plant from anywhere with internet access, so major issues can be identified and resolved quickly, even after hours.

Electrical safety is paramount at asphalt plants, where severe conditions like dust, heat and moisture can trigger devastating faults. To protect both employees and equipment, the control system needs appropriate grounding, sturdy wiring, and modern circuit breakers that trip if anything goes awry.

Routine inspections, such as verifying tight terminals, testing relays, and calibrating sensors, are simple yet critical. Cleaning control cabinets and testing breakers and contactors keeps things in shape. If the plant encounters voltage swings or short circuits, the control system must absorb them without endangering personnel or equipment.

Well-labeled and clear fault codes allow staff to identify and resolve issues without trial and error. Tracking data in real time gives plant staff the advantage of anticipating trends, scheduling repairs, and adjusting the process for maximum yield.

Sensors provide constant data to the PLC and panel, allowing the team to detect items such as bearing wear or a slowed feeder. With this data, they can schedule repairs before a minor problem closes down the line. Real-time data assists with quality, too, as mix specs can be monitored and modified on the fly.

All this leads to less downtime, less waste, and more control over costs.

Dust Removal & Environmental System: Main Components and Working Principle

Dust removal is integral to any modern asphalt plant. It means cleaner air, compliance with rigorous regulations, and health protection for workers and neighbors. A great deal of the dust originates from drying the stone and then mixing it with asphalt. Both of these steps stir up fine particles, which, if not captured, can damage air quality and the environment.

The drying drum and kiln alone are the biggest culprits, accounting for around 35 percent of all dust emitted. At the center of your dust control system is the dust collector. It consists of a collector housing, filter bags, a hopper, and a cleaning system. When dusty air enters, it impacts the filter first.

Filter bags, long tubes of robust fabric, are used in most plants. As the dust-laden air passes, the bags capture dust on their surface. Layer by layer, it accumulates. The collector’s hopper is cone-shaped, typically at 60 degrees or greater, so dust falls down without caking or clogging. Once the dust is collected, it falls out of the system for safe disposal.

Bag filters are the most commonly used filters in asphalt plants. They are easy to swap out, usually every 3 to 5 years, depending on how much dust there is, the type of dust, and how well the system is cared for. Keeping the filters in shape means checking them regularly, cleaning them, and ensuring no leaks or tears have developed.

If you notice higher pressure inside the collector or if dust cakes up too much, it’s time to take a closer look. Ducts, seals, and access doors, for instance, should all be inspected as part of routine maintenance. The cyclone dust collectors are often added before bag filters. These utilize a cyclonic action to fling heavy dust to the walls and down to the bottom.

They’re small, don’t occupy much space, and resist high temperatures well. Cyclones are effective for dust ranging from 10 to 200 micrometers. This makes them a good match for primary dust control in hot, dusty locations such as the drying drum.

Great dust systems do more than catch dust. They assist plants in complying with regulations, such as the Air Pollution Prevention and Control Law and the Environmental Protection Management Regulations of Construction Projects. They require plants to utilize certified dust collectors and maintain maximum permissible emission limits.

Without them, plants can be hit with harsh fines or worse, having to close up.

Key Differences between Hot Mix Asphalt Plant Exclusive Components and Cold Mix Asphalt Plant Simplified Components

Hot mix and cold mix asphalt plants function differently and require different key components. The primary distinctions are their treatment of heat, moisture, and equipment. This alters the arrangement of each plant, its requirements, and its utilization on jobs. Knowing these differences assists project teams in choosing the appropriate method for their requirements.

|

Component/Process |

Hot Mix Asphalt Plant |

Cold Mix Asphalt Plant |

|---|---|---|

|

Temperature Requirement |

135°C–175°C (275°F–350°F) for mixing and drying |

No high heat needed; mixes at ambient temperature |

|

Core Equipment |

Rotary drum, superheaters, dryers, conveyors, pavers, rollers, trucks |

Pug mill or drum mixer, shovels, hand tampers, plate compactors |

|

Curing Mechanism |

Cools by losing heat after laying |

Sets by solvent or water evaporation, or compaction |

|

Moisture Sensitivity |

Needs dry aggregates, moisture removal is vital |

Less sensitive; can work with damp aggregates |

|

Asphalt Binder |

Needs more viscous binder, designed for heat |

Uses cutback or emulsified binders, less viscous |

|

Aggregate Requirements |

Precise gradation, must dry and heat aggregates |

Broader gradation, no need to heat or dry |

|

Weather Limitations |

Needs dry, warm weather for quality paving |

Can work in cold, wet, or variable weather |

|

Open to Traffic |

24–48 hours after paving |

Sometimes immediate, after compaction |

Hot mix asphalt plants involve more steps and complicated machines. First, they heat and dry stone, sand, and gravel in a rotary drum, which requires heavy fuel use and sensitive heat control. The hot binder then bonds with dry aggregates. Pavers, rollers, and other tools form and compact the mix on the road.

Workers have to monitor moisture since even a little bit can compromise the bond and cause cracks eventually. Once it is laid down, hot mix has to cool before vehicles can drive on it, sometimes taking a full day or more.

Cold mix asphalt plants don’t require heat. Instead, they utilize binders that act at ambient temperatures, such as emulsified or cutback asphalt. These binders coat the aggregates without drying or heating. It operates with primitive mixers and rudimentary hand implements, rendering cold mix more suitable for inaccessible locations or minor fixes.

Cold mix can be set by water or air drying or by pressing with a tamper or small compactor. As it does not rely on heat, cold mix can be used in wet or cold weather and is less stringent on aggregate size and dryness.

Temperature changes everything about the layout of each plant. Hot mix has to maintain the heat, so it utilizes insulated tanks, burners, and massive drums. Cold mix bypasses much of this equipment and requires less upkeep.

Hot mix plants are usually larger, require more specialized workers, and consume more electricity. Cold mix plants can be small, mobile, and easy to run with fewer people.

For project teams, these distinctions imply hot mix is ideal for large, regulated projects such as highways or airport runways. It provides powerful, permanent repairs but requires advance notice, nice weather, and expensive equipment.

Cold mix is ideal for quick repairs, smaller roadways, or areas where weather and speed take precedence over durability. This means work can continue in rain or cold, with no waiting.

Aggregate Drying & Heating System

The core components are a rotary dryer and a burner, which dry the wet aggregate to a moisture content of less than 0.5% and heat it to 160-200°C to prepare for high-temperature mixing. The burner commonly uses diesel, natural gas, or heavy oil as fuel.

Learn More

Hot Aggregate Elevator & Screening System

Includes a bucket elevator and a vibrating screen, which lifts and grades the dried and heated aggregates into different sizes and sends them to the hot aggregate bin for temporary storage, adapting to precise batching.

Learn More

Asphalt Heating & Insulation Device

Asphalt storage tanks are equipped with thermal oil heaters/steam heating systems to heat the road petroleum asphalt to 150~180℃, ensuring the asphalt’s fluidity and facilitating transportation and feeding.

Learn More

Technical Guidelines for Asphalt Plant Component Maintenance

Regular maintenance of asphalt plant components is essential for reliable, efficient, and consistent production. Every component—mixers, dryers, feeders, silos, burners—operates round the clock in demanding environments. Proper maintenance prevents equipment from breaking and saves money. It aids in complying with stringent mix and plant safety regulations.

-

Inspect all components regularly, looking for cracks, leaks, heat marks or loose bolts. Inspections assist in identifying minor malfunctions before they develop into significant defects. Concentrate on hot spots such as the drum shell, mixing arms and bearings. Take checklists for each and keep records for wear trends over time.

-

Wash moving elements, such as conveyor belts and augers, to prevent accumulation and clogs. Dust and debris will gum up work and cause jams. Use air blowers or even simple brushes. Never miss a cleaning, even on busy days. It keeps the plant running smoothly.

-

Maintain the oil and grease levels right for all moving parts. Dry bearings or chains wear out quickly and can cause unexpected shutdowns. Use the proper grade of grease and oil, and log service dates on a chart. For instance, drum mixers require grease every 100 hours, whereas conveyor bearings might require weekly inspections.

-

Inspect burner units for clean fuel lines and nozzles. Caked burners reduce heat and waste fuel. Clean or replace filters and monitor for soot deposition on a monthly basis. A clean burner maintains proper mix temperatures and conserves energy.

-

Keep an eye on dryer drums for heat stress, warped metal or loose flights. Drums get pummeled by heat and rocks. A simple hammer test on drum shell soundness and tightening bolts as necessary.

-

Check silo gates and level sensors. Silo gates are notorious for sticking, especially if they aren’t cleaned or if seals have worn away. Sensors require clear lenses for accurate readings. Change gaskets and inspect wiring regularly. These components maintain mix flow constant.

-

Check control panels and wiring for loose connections or wear. Electrical faults are a major reason for plant stops. Safe steps to check panels and replace fraying wires or weak relays. Label wires for quick fault finding.

-

Replace consumables, such as belts, chains, and filters, on a predetermined schedule. Don’t wait for them to break. Employ a logbook to monitor part life and replace parts before they break down. This reduces unexpected halts and keeps crews moving.

-

Educate technicians on every maintenance step, from oil checks to system resets. Use explicit instructions and practical exercises. Experienced crews identify problems earlier and repair them correctly the first time.

-

Establish a routine schedule for every type of job: daily, weekly, and monthly. Use digital logs or even simple wall charts. Schedule jobs during off work hours to reduce downtime.

Frequently Asked Questions

What are the main components of an asphalt plant?

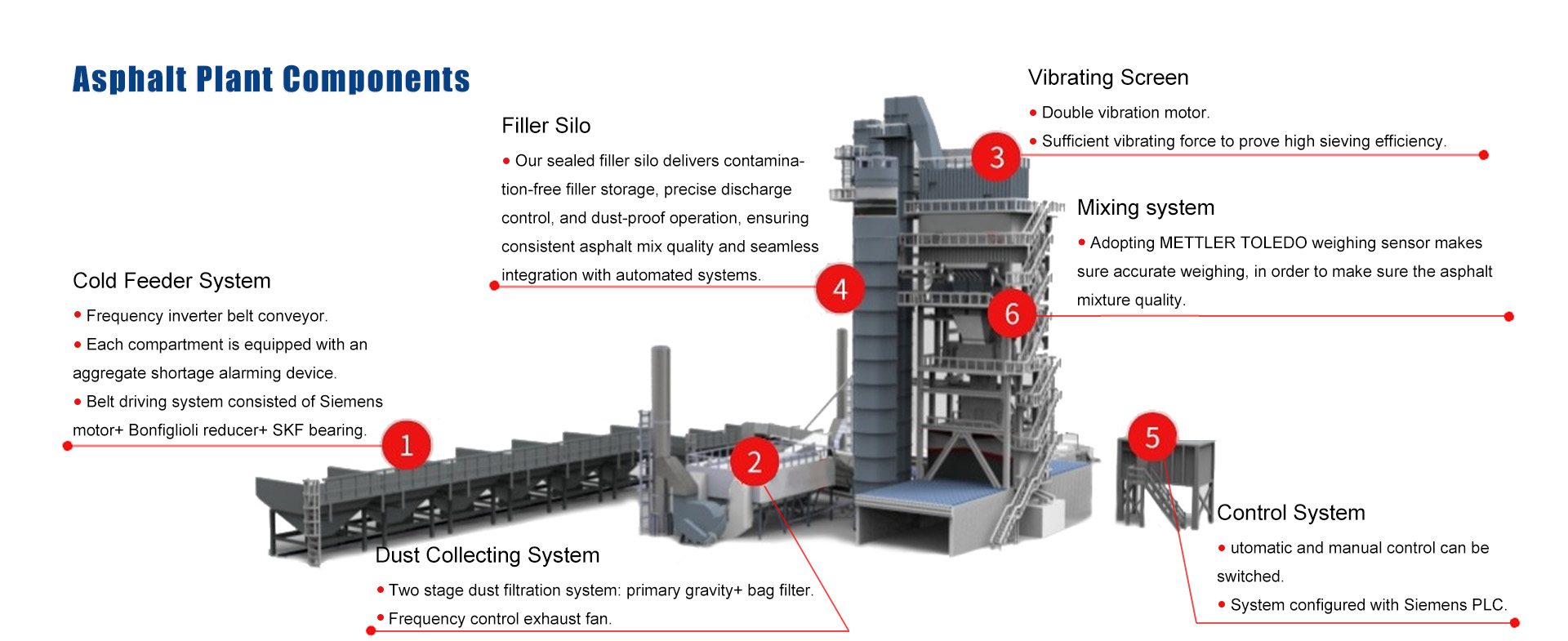

The core composition of an asphalt plant’s main components includes the aggregate batching mixing system, asphalt supply system, filler supply system, finished mix storage system, electrical control system, and dust removal or environmental system.

How does the mixing system in an asphalt plant work?

From the outside, the mixing system intimately stirs the aggregates, asphalt, and fillers. It employs a rotary drum or mixer arms to evenly coat, resulting in a consistent and superior asphalt blend.

Why is the dust removal system important in asphalt plants?

Our dust removal system safeguards the environment and workers by capturing dust and particulates during production. It guarantees environmental regulations and increases air quality near the plant.

What is the difference between hot mix and cold mix asphalt plant components?

Hot mix asphalt plants contain specialized equipment used for heating and precise mixing. Cold mix plants utilize fewer, simpler components as they are non-thermal plants.

How often should asphalt plant components be maintained?

Regular maintenance is advised, usually weekly or monthly based on usage. Regular inspections stave off breakdowns and increase equipment longevity.

What makes a superior asphalt mixing plant component?

Our quality components provide extended life, energy savings, precise control and ease of maintenance. These features enhance plant productivity, minimize downtime and optimize asphalt quality.

Can asphalt plant systems be upgraded for better performance?

Yes, almost all asphalt plant parts are upgradeable. Plant upgrades might involve new control systems, enhanced dust extraction equipment, or more efficient mixers to optimize productivity and reduce operating expenses.

CONTACT US