1️⃣ What Is a Concrete Batching Plant?

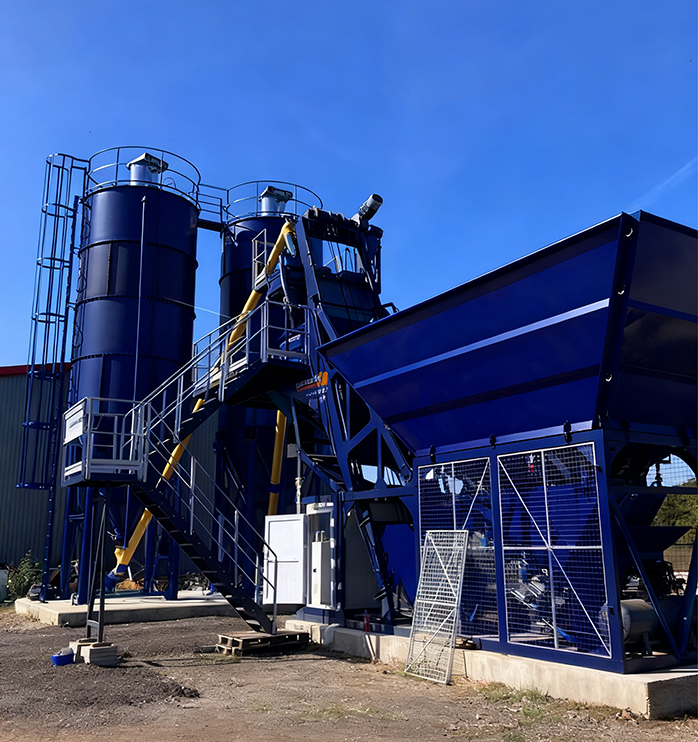

A concrete batching plant is a system that combines different materials—cement, sand, water, and aggregates—into high-quality concrete. It ensures accurate proportioning and consistent mixing results, which directly affect the strength and durability of concrete. Whether for highways, bridges, or precast factories, batching plants are the backbone of every concrete project.

2️⃣ The Main Types of Concrete Batching Plants

There are several types of batching plants, and choosing the right one depends on your project needs.

A. Stationary Concrete Batching Plant

Designed for large-scale and long-term projects. It offers higher productivity, stability, and automation.

👉 Best for: Ready-mix factories, infrastructure projects, precast yards.

B. Mobile Concrete Batching Plant

Built for flexibility. It can be transported and installed quickly, ideal for remote areas or temporary projects.

👉 Best for: Road construction, bridge repair, mobile job sites.

C. Compact or Mini Batching Plant

Small footprint, easy installation, and affordable cost.

👉 Best for: Small contractors, startups, and limited-space areas.

3️⃣ How a Concrete Batching Plant Works

-

Aggregates are loaded into bins and weighed.

-

Cement and water are measured precisely.

-

All ingredients are transferred to the mixer.

-

The mixer blends them until a uniform concrete mixture is produced.

-

Finished concrete is discharged to trucks for delivery.

⚙️ Accurate weighing and automation control are key to achieving consistent concrete quality.

4️⃣ How Much Does a Concrete Batching Plant Cost in 2025?

Prices vary based on capacity, automation level, and mobility:

| Type |

Capacity |

Price Range (USD) |

| Mini plant |

25–35 m³/h |

$20,000–$40,000 |

| Mobile plant |

50–100 m³/h |

$45,000–$90,000 |

| Stationary plant |

90–180 m³/h |

$60,000–$150,000 |

💡 Tip: Always consider total cost (shipping, foundation, installation, and training) before purchase.

5️⃣ Key Factors to Consider Before Buying

-

Production capacity: match with daily concrete demand.

-

Automation level: PLC control increases accuracy.

-

Mobility: choose mobile if project sites change often.

-

Spare parts & service: ensure quick local support.

-

Manufacturer reputation: real projects and after-sales service matter most.

6️⃣ Why Choose SDCAD Concrete Batching Plants

SDCAD offers full-scale batching plant solutions—from design and manufacturing to installation and after-sales support.

-

Over 15 years of export experience

-

Customized layouts for site requirements

-

Factory-direct price with CE/ISO certifications

-

Professional engineers for on-site training

🚀 Contact SDCAD today to get a tailored solution and quotation within 24 hours.

7️⃣ FAQs

Q1: How long does it take to install a batching plant?

A: Mobile plants can be set up within 3–5 days; stationary ones take about 15–20 days.

Q2: What is the lifespan of a concrete batching plant?

A: 10–15 years with proper maintenance.

Q3: Can SDCAD customize plant layout?

A: Yes. Our engineers design layouts based on your site size, foundation, and production goal.

8️⃣ Conclusion

A concrete batching plant is more than a piece of equipment—it’s the foundation of efficient, high-quality construction.

If you want to boost productivity, reduce concrete waste, and get a long-lasting solution, SDCAD is your reliable partner.

👉 Get a free design and quotation now.