Welcome to SDCAD Official Website! Email: admin@sdcadi.com

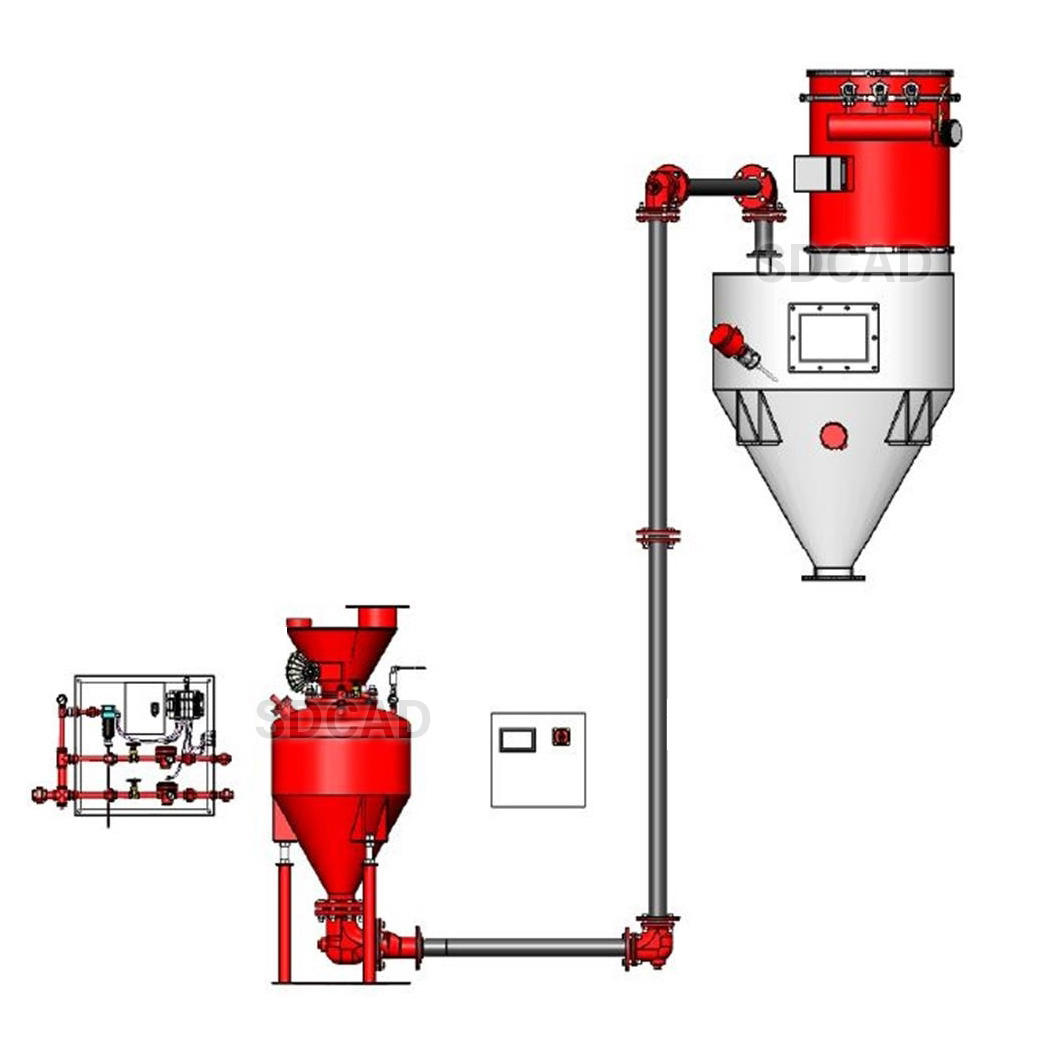

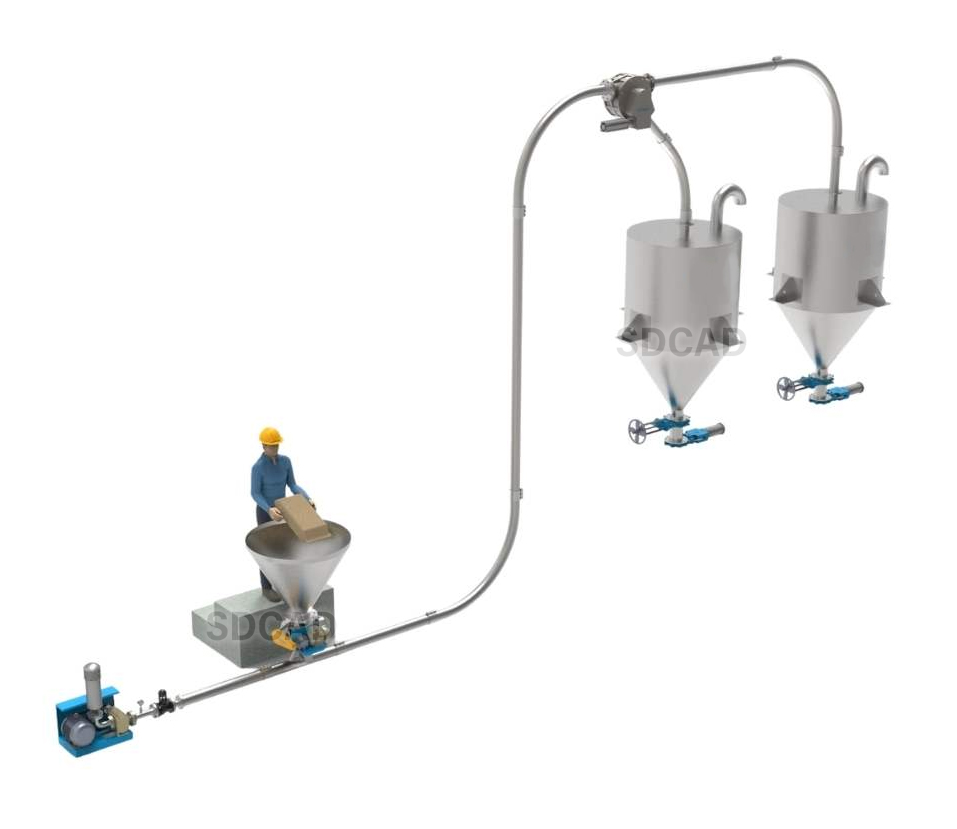

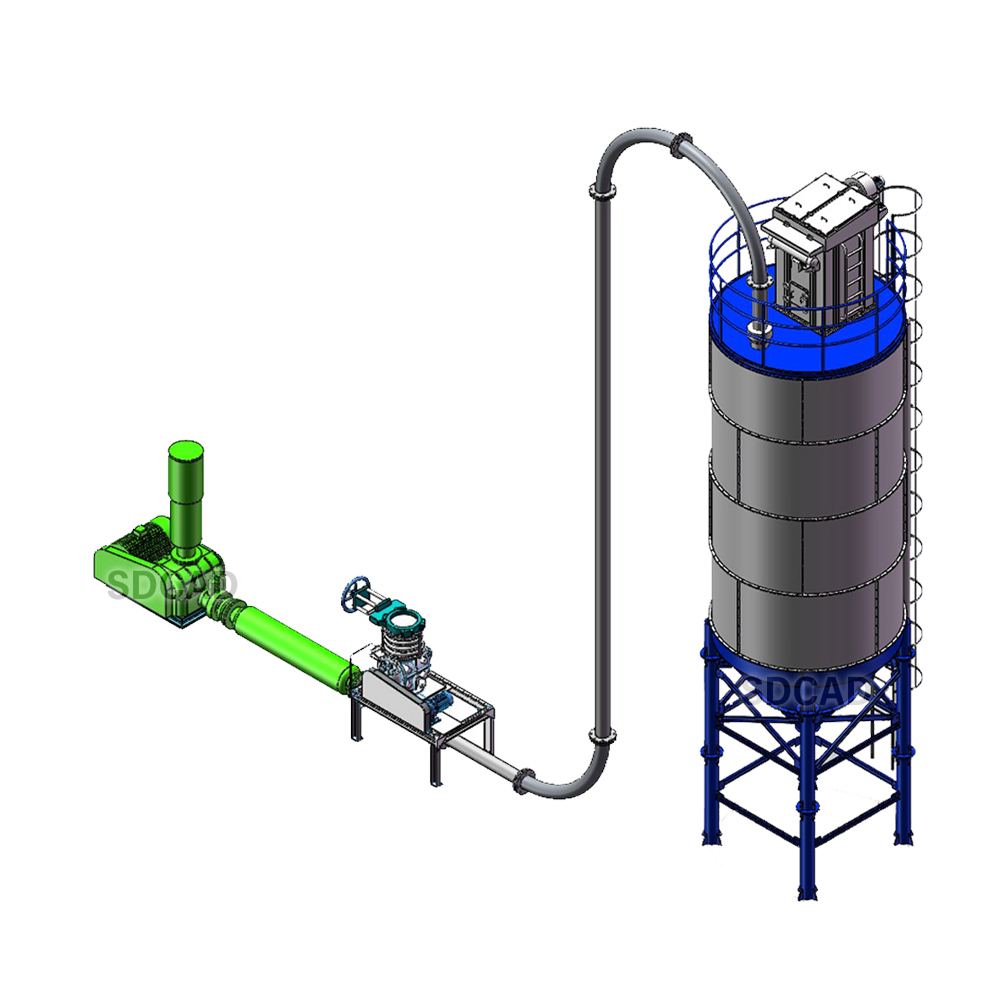

Pneumatic Conveyor

Pneumatic conveyor is a necessarily custom-made conveying system & based on product characteristics, particle size, throughput capacity, number of sources, and number of destinations.

Classification:

The forms: Pneumatic conveying are the dilute phase and dense phase.

The types: Pneumatic conveying are pressure and vacuum.

Specifications

|

Project |

Conveying capacity(t/h) |

Conveying Pressure(kPa) |

Conveying distance(m) |

Diameter of conveying pipe(mm) |

|

Parameter |

≤100 |

≤196 |

≤300 |

≥25 |

Advantage:

Pneumatic conveying systems are not just a cleaner alternative—they represent the future of bulk material handling. Pneumatic systems are ideal for industries like chemicals, building materials, food processing, and pharmaceuticals.

-

Can adapt to complex routing needs.

-

May eliminate the need for a bucket elevator, simplifying the design.

-

Faster installation

Social Media

Page Copyright: SHANDONG CAD INDUSTRY MACHINERY EQUIPMENT CO. LTD.