Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact UsAsphalt Mixing Plant

As a core piece of equipment in road construction, asphalt mixing plants are crucial for ensuring the precision, stability, and high quality of asphalt mixture production. The asphalt mixtures they produce are widely used in the construction, routine maintenance, and emergency repair of various transportation infrastructure projects, including highways, urban arterial roads, secondary roads, rural roads, bridges, tunnels, and parking lots. The technical level and operational stability of asphalt mixing plants directly influence the mix proportion accuracy, mixing uniformity, and performance consistency of the mixture, serving as the first critical line of defense in the road engineering quality control system. Choosing asphalt mixing equipment suitable for the project’s needs not only allows for precise control of the mixture quality, ensuring the project meets design standards and usage requirements, but also shortens the construction cycle and reduces raw material waste through efficient production processes, thereby improving construction efficiency, optimizing labor costs, and reducing overall construction costs. Let’s delve into the core equipment composition and operational logic of asphalt mixing plants to explore how they empower and enhance road construction.

Choicing tyles of asphalt plants is determined by various factors, such as project scale and capacity requirements, site conditions, raw material supply and storage, and environmental and compliance requirements. Selecting a suitable types of asphalt plants can significantly improve production efficiency, reduce costs, and minimize waste for investors. Below, we provide information on different types of asphalt mixing plants and their advantages for your reference.

Advantages & Features

Advantages & Features

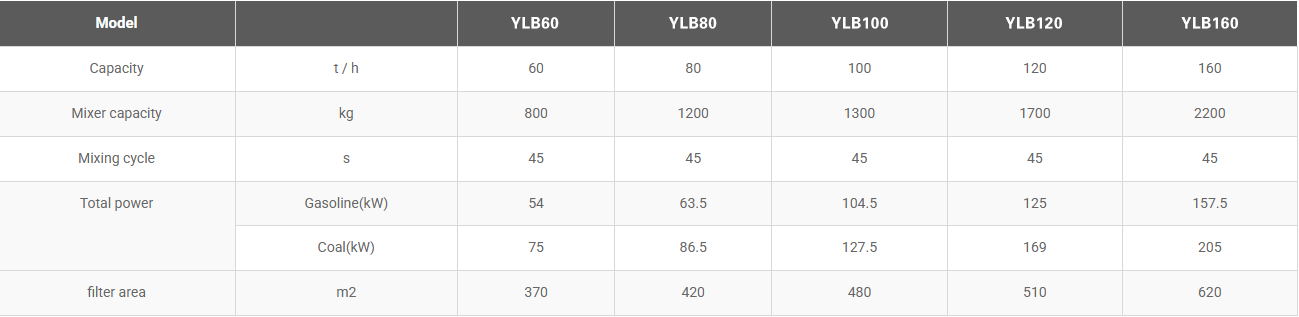

In asphalt pavement engineering, selecting the right asphalt mixing plant specifications is a core prerequisite for ensuring construction efficiency, controlling production costs, and ultimately producing high-quality asphalt mixtures. Key parameters such as production capacity, the sophistication of the mixing process, and the choice of fuel type directly determine the project’s construction pace, cost input, and the final pavement’s durability.

This detailed specifications guide will break down the equipment selection logic for different scenarios based on actual engineering needs, helping you accurately match your project positioning and lay a solid foundation for pavement quality through professional selection.

Our LB stationary asphalt batch plant (Cold Climate Version) is purpose-engineered to deliver unwavering performance even in temperatures plummeting to -40°C, guaranteeing seamless, high-efficiency asphalt production even in the harshest winter conditions.

Engineered from the ground up for extreme cold, it addresses the unique challenges of low-temperature asphalt manufacturing, from material handling to heat retention.

Here are the stand-out features that establish it as the go-to solution for cold climate operations:

Choosing the wrong asphalt mixing plant can disrupt your project schedule, exceed your budget, and affect pavement quality. This guide will help you navigate the complexities and match the right capacity, transportation capabilities, and budget to your project’s specific needs, avoiding costly mistakes and selecting a mixing plant that delivers reliable, long-term performance.From a construction perspective, we break down the pain points, adaptation solutions, and practical suggestions for different scenarios, focusing on four core dimensions: project scale, special scenario requirements, construction cycle flexibility, and climate and geological conditions. This helps you accurately match equipment, avoid selection pitfalls, and ensure efficient project progress.

1. Small-Scale Scenarios: Small-scale road repairs, courtyard paving, community branch road construction

Customer Needs: Small equipment size, easy mobility, simple operation, no need for a professional maintenance team, low single-batch output but quick start-up and shutdown, suitable for narrow sites, and controllable initial procurement costs.

Suitable Solution: Recommended small mobile asphalt mixing equipment (portable or towed) with a capacity of 5-20t/h. Integrated design models are preferred, requiring no complex installation and commissioning; simply plug in to operate.

2. Medium-Scale Scenarios: Medium-scale road repairs, county-level infrastructure projects, industrial park road construction

Customer Needs: Moderate capacity, balancing stability and mobility, capable of multi-site turnover, controllable maintenance costs, adaptable to different aggregate types, and meeting medium-intensity construction needs.

Suitable Solution: Recommended semi-mobile or modular asphalt mixing equipment with a capacity of 20-80t/h, supporting rapid assembly and disassembly (transfer and commissioning completed within 48 hours), equipped with a multi-hopper design, compatible with various aggregates, and featuring an intelligent control system for simplified operation.

3. Large-Scale Scenarios: Large-scale road projects, highway construction, and municipal arterial road renovation

Customer Requirements: High production capacity, high stability, capable of 24-hour continuous operation, high precision in mixture quality, adaptable to large-scale aggregate supply, compatible with intelligent construction management systems, and meeting stringent quality acceptance standards.

Suitable Solution: We recommend large-scale stationary asphalt mixing equipment with a capacity of 80-240 t/h, equipped with a precise metering system (aggregate and asphalt metering error ≤ ±0.5%), a high-efficiency combustion system and waste heat recovery device, supporting integration with BIM and intelligent scheduling systems, and equipped with a dedicated maintenance team and spare parts warehouse.

1. Projects in Remote/Infrastructure-poor Areas

Customer Requirements: Equipment with strong weather resistance and low failure rate, adaptable to unstable power/fuel supply conditions, readily available spare parts, convenient transportation, and no reliance on complex supporting facilities.

Suitable Solutions:Select simple, low-failure-rate mobile or semi-mobile equipment equipped with a dual-fuel system (diesel + natural gas, switchable to adapt to local energy supply), featuring large-capacity fuel and water tanks, and sealed silos to prevent aggregate from becoming damp and clumping; incorporate a remote diagnostic system to reduce reliance on on-site maintenance.

2. Projects with Strict Environmental Requirements

Customer Needs: Meet local environmental standards for dust, noise, carbon emissions, and asphalt fume emissions to avoid work stoppages and fines due to non-compliance, balancing environmental protection and production efficiency.

Suitable Solutions: Recommended equipment includes fully enclosed silos, pulse-jet bag filters (dust emission concentration ≤10mg/m³), and asphalt fume purification devices; employ low-noise mixing units and soundproof enclosures (operating noise ≤75dB); optional thermal recycling systems (recycled material blending ratio up to 30%-50%) reduce carbon emissions and raw material consumption; some models can be integrated with carbon footprint monitoring systems.

3. Projects with Limited Budgets and a Focus on High-Performance Equipment

Customer Needs: Controlling initial procurement costs while balancing equipment reliability and operational economics; prioritizing “low-cost + highly adaptable” models to avoid redundant features.

Adaptability Solutions: For small to medium-sized projects, choose cost-effective domestic brand equipment (using well-known brands for core components to reduce the risk of failure), or high-quality used equipment (with professional inspection reports to ensure core components have no major repair history); for large projects, consider leasing models for flexible scheduling and reduced depreciation pressure.

1. Short-Term Emergency Projects: Road repair, post-disaster reconstruction, temporary access road construction

Customer Needs: Fast equipment deployment, flexible start-up and shutdown, rapid production of qualified mixes, adaptability to temporary construction sites, and no complex preliminary preparations required.

Suitable Solutions:1. **Portable Asphalt Mixing Equipment:** Portable asphalt mixing equipment with a capacity of 10-40 t/h, featuring an integrated design that can be directly towed to the site and start operation within one hour of power/oil connection. Equipped with a simple batching system, it supports rapid adjustment of the mix ratio, meeting the quality and timeliness requirements for emergency repairs.

2. Long-Term Fixed Projects:Large-scale industrial park infrastructure, highway reconstruction and expansion, and long-term municipal engineering projects.

Customer Requirements:Highly stable equipment with ample capacity, capable of continuous long-term operation, controllable maintenance costs, adaptable to the entire project lifecycle, and low depreciation rate.

Suitable Solutions: Large-scale fixed asphalt mixing equipment is recommended, equipped with a comprehensive maintenance system (regular maintenance reminders, fault early warning), and employing a high-efficiency energy-saving design (waste heat recovery, low-fuel-consumption burners) to reduce long-term operating costs. Capacity can be adjusted in stages according to project progress to avoid initial overcapacity.

3. Multi-site Relocation Projects: County-level road repairs, township infrastructure projects, and cross-regional construction projects.

Customer Needs: Easy equipment assembly and disassembly, low relocation costs, rapid adaptation to different site conditions, and stability across various operational scenarios.

Adaptation Solution: We recommend a semi-mobile modular asphalt mixing plant. After disassembly, it can be transported by conventional trucks. On-site assembly and disassembly do not require large hoisting equipment, and commissioning can be completed within 24-48 hours. Equipped with adjustable outriggers and a simple positioning system, it adapts to different site terrain conditions.

1. High-Altitude/Permafrost Region Projects: Construction in Siberia and other high-altitude cold regions.

Customer Needs: Equipment with low-temperature start-up and anti-freeze insulation functions to withstand severe cold weather. The mixture should maintain a stable temperature to avoid freezing losses.

Supplementary Solution:Select a low-temperature specialized asphalt mixing plant, equipped with a motor heating jacket, hydraulic oil heating system, and asphalt insulated storage tank (insulation layer thickness ≥120mm). The mixing silo features a windproof and heat-insulating design. The combustion system is upgraded to a high-power cold-start ignition device to ensure normal start-up at -40℃. A hot material transfer silo is included to reduce heat loss during mixture transportation.

2. High-Temperature/High-Humidity Area Projects: Construction in Southeast Asia, South American rainforests, and tropical Africa.

Customer Requirements: The equipment must be corrosion-resistant, rainproof, and moisture-proof, capable of controlling the mixture temperature (preventing high-temperature softening), and suitable for damp aggregates to prevent clumping and blockage.

Supplementary Solution:The main body of the equipment is treated with an anti-corrosion coating. The electrical cabinet is equipped with a dehumidifier and rain cover. The silo features a sealed design with a ventilation system to prevent aggregate from becoming damp and clumping. The mixing host has an optimized heat dissipation structure, coupled with an asphalt cooling device to ensure the mixture temperature meets standards. The conveyor belt is made of high-temperature resistant and corrosion-resistant rubber to extend its service life.

3. Desert/Dust-Prone Area Projects: Construction in arid and sandy regions of the Middle East and Africa

Customer Requirements: Equipment with dustproof sealing to filter airborne sand particles, prevent component wear, and be suitable for dry aggregates to reduce dust pollution.

Suitable Solution: Select a fully sealed asphalt mixing plant with sealed hoppers, mixing chambers, and conveyor belts. Equipped with a high-efficiency dust recovery system (pulse dust collector + sand filter); dust covers are added to core components such as motors and bearings; the lubrication system uses high-viscosity dust-proof lubricating oil; the aggregate pretreatment system is upgraded to a screening and sand removal device to ensure aggregate purity.

4. Complex Geological (Mountainous/Rocky) Area Projects: Construction in mountainous areas, mining roads, and hilly regions

Customer Requirements: Equipment suitable for narrow spaces and complex terrain, capable of handling large aggregates, convenient transportation (suitable for mountain roads), and high stability (resistant to terrain bumps).

Suitable for: Small and medium-sized projects are recommended to use small towed asphalt mixing equipment. The machine body is compact and flexible, making it suitable for narrow roads in mountainous areas. It is equipped with a large aggregate crushing and screening system, which can directly process aggregates on site and reduce transportation costs. The equipment outriggers are adjustable to adapt to the uneven terrain of hilly areas and ensure stable operation.

Price is a crucial consideration when purchasing an asphalt batching plant. SDCAD asphalt batching plants range in price from $50,000 to $1 million, depending on type, capacity, and configuration. However, the price is only one part of the total investment; several other factors must be taken into account.

Planning ahead to improve production efficiency, especially a series of measures during the production process, is particularly important and prominent. Below, we introduce several points for reference in our future planning.

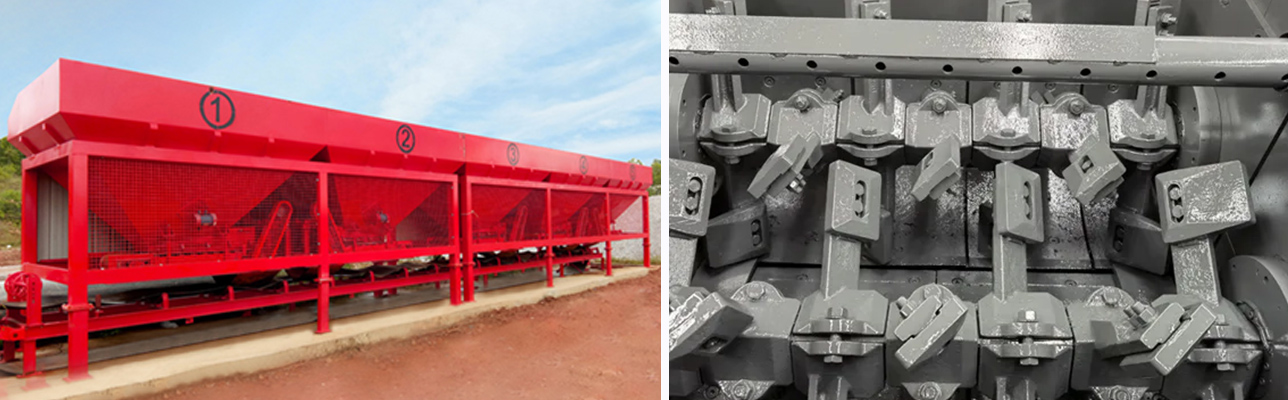

The key asphalt plant components determine its efficiency and quality consistency. The plant comes with cold bins or hoppers to feed in the raw stone and sand. These bins keep materials separated and feed them in fixed quantities.

Every plant has a drying system that utilizes a burner to dry and heat these materials. Drum plants do this in one drum, while batch plants have a separate drying drum and mixer.

This machine combines the hot, dry stone with asphalt binder and any additional additives. A powerful mixer results in a homogeneous mixture. Quality in this context means fewer lumps and improved production.

Dust cleaning equipment, the first dust storm washing machine used, does not pollute the air and allows for convenient maintenance.

The control system is the plant’s brain. It monitors and controls the materials flow, heat, and each major process. A stable control system maintains output at a high rate and minimizes waste.

Every component, including bins, dryer, burner, asphalt plant mixer, dust remover, and asphalt plant control system, contributes to efficiency. See the following diagram for a basic layout:

[cold bins] –> [dryer and burner] –> [dust remover] –> [mixer] –> [storage and loading]^ | | v[Control System oversees and regulates all processes]

We are committed to providing high-quality asphalt mixing plant china and related services to global customers. As one of asphalt plant suppliers, we focus on building trust and providing a seamless service experience. In addition to customizing the best pre-sales and sales services for asphalt mixing plants according to customer needs, we also place great emphasis on after-sales service.

What We Provide: Global Asphalt Mixing Plant Services Our services provide plant owners a comprehensive toolset to increase daily production and control costs. Manufacturers now provide full-service packages, like routine checks, parts replacement, and system upgrades, that help minimize material loss during starts and stops.

Take, for example, start-ups and shut downs—no mix lost, up to 8 tons at a time, which accumulates quickly. Our after-sales support is a differentiating factor for plant life. Quick problem response, twice-a-day moisture checks, assistance with air leak repairs, and bag inspections all keep the plant humming.

Operator training programs emphasize safety, but they instruct the latest techniques for counter-flow drums and variable frequency drives, which better heat aggregates and reduce drying costs. These plans demonstrate how to process higher RAP content, implement fractionation, and reduce mix temperature, which can reduce fuel consumption by up to 14 percent.

Tech enhancements, such as digital monitoring and process control upgrades, allow customers to follow every aspect of plant operations in real time. They offer owners the means to make intelligent decisions, reduce fuel wastage, and increase mix quality.

Among our asphalt plant for sale, the proportion of asphalt batch plant and drum plant has always been very high. So let us briefly introduce the differences between the two and provide some suggestions for customers to make a better choice.

Now batch plant vs. Drum plant trade-offs in asphalt production. Batch plants operate by mixing fixed quantities of materials for each batch, enabling precise control over the proportions and quality of the final mix.

Drum plants operate 24/7, delivering and combining aggregate and bitumen in an uninterrupted stream, enhancing energy conservation and maintaining consistent production. For instance, a batch plant is ideal for jobs requiring various asphalt formulas or highly accurate blends, whereas a drum plant aligns with big, high-speed highway projects.

Batch plants have greater initial and operating costs because of their complicated configuration and regular servicing. Drum plants are cheaper, require less space, and can be installed rapidly, making them ideal for projects operating on a shoestring or with limited sites.

The ongoing process characteristic of drum plants implies less flexibility in adapting mixes on the fly, which can impact quality for specialty jobs. Batch plants provide more flexibility for modifications and experimentation during each batch.

Below is a quick comparison:

|

Feature |

Batch Plant |

Drum Plant |

|---|---|---|

|

Production |

By batch |

Continuous |

|

Quality Control |

High, precise metering |

Moderate, less flexible |

|

Efficiency |

Lower, more stops/starts |

High, fewer stops/starts |

|

Space Needed |

Larger footprint |

Compact, small footprint |

|

Cost |

Higher initial and running costs |

Lower costs |

|

Best Use Case |

Specialty/high-quality jobs |

Large-volume/fast jobs |

Green asphalt plant puts eco-balance at the center of its process, making a definite move toward asphalt sustainability. When plants embrace green tech, such as warm mix asphalt technology, they can reduce hydrocarbon emissions and operate at lower temperatures. This measure is not only of assistance to the environment but also cuts energy consumption drastically.

For example, by reducing aggregate moisture by only 1%, plants save approximately 27,100 BTU per ton, demonstrating how minor changes can lead to significant energy reductions. By utilizing recycled materials like RAP, they reduce virgin inputs and greenhouse gas emissions.

Plants equipped with energy-efficient equipment, advanced control systems, and variable frequency drives demonstrate increased flexibility and reduced waste while maintaining a lean and clean process.

Real-life examples, such as urban asphalt plants in Germany and the Netherlands, have demonstrated that making the switch to green operations has advantages that extend well beyond the plant. Local communities experience cleaner air, reduced waste, and roads that last longer, which results in reduced costs and less intrusion.

In an industry that continues to evolve, targeting net-zero emissions will require innovative approaches, as existing measures are still insufficient.

Asphalt mixtures are notable for their broad use in road construction and infrastructure. Performed for roads, highways, airport runways, and parking lots, these mixtures provide smooth, durable surfaces that withstand heavy traffic and extreme weather. Many cities use them for bike paths, walkways, and playgrounds, as asphalt quiets noise and increases safety for everyone.

Warm mix asphalt aids in reducing emissions during paving. Lower mixing temperatures mean less energy and fewer fumes, which is a win for crews and the environment. Dense urban zone projects or those near schools are frequent users of warm mix asphalt for these reasons.

Recycled asphalt pavement, or RAP, is emerging as a top pick for green builds. When crews mix old asphalt with the new, they save natural resources and keep waste out of landfills. This transition aids green objectives worldwide.

Transportation and infrastructure are the biggest beneficiaries of asphalt. Airlines require hard-wearing runways and local authorities insist on secure, durable roadways. Asphalt even contributes to roofing, with shingles and coatings for homes and businesses.

Asphalt mixtures are customizable for each project, such as higher friction for tight corners or added durability for high-traffic intersections.

Asphalt Concrete Market leads the growth with global infrastructures and persistent road network expansions. Market trends trend toward more warm asphalt mixes, now used from Europe to Asia, as these mixes reduce energy consumption and adhere to stringent emission regulations. Many plants are using RAP, some as high as 50% RAP. This transition aids in saving raw materials and reducing costs.

Infrastructure spending drives demand. When new highways are funded by governments or old roads are repaired, asphalt use increases. This lift not only expands the market but pushes plants to increase both production and productivity. These days, mixing plants sport modular setups for small city jobs or large national projects.

Tech upgrades shift plant efficiency. New burners and mixers reduce fuel consumption by as much as 14 percent, while sensors and controls maintain quality. Greater RAP use drives plant makers to develop more resilient, intelligent equipment. Quality standardization is crucial. Manufacturers sample test batches to comply with road safety and durability specifications.

Here are key players in the market:

|

Company |

Main Contribution |

|---|---|

|

Ammann Group |

Modular plants, high RAP integration |

|

Benninghoven |

Eco-friendly burners, digital controls |

|

Astec Industries |

Custom plants, quality control systems |

|

Marini |

Energy efficient designs, warm mix tech |

As one of China’s most popular asphalt plant manufacturer, we hope you will become our asphalt mixing plant distributor – let’s achieve success together! As a distributor, you will support large-scale infrastructure projects and meet the market’s ongoing demand for high-quality asphalt mixtures.

The key advantages of becoming an asphalt mixing plant distributor include:

Key benefits of becoming an asphalt plant distributor include:

Stable demand from construction companies needing timely materials

Access to training and technical support for ongoing operations

Opportunities to use advanced inventory and logistics systems

Direct relationships with suppliers and contractors

Potential for year-round business, with seasonal peaks

Distributors get resources such as equipment training, marketing materials, and live inventory tools. Technical teams provide assistance with installation, operation, and troubleshooting.

These supports enable new distributors to establish a solid foothold and stay abreast of market trends and regulations. For example, smart logistics software can plan routes, track stock levels, and cut delivery delays.

Earnings opportunity in the asphalt business is as robust as ever in markets where infrastructure demands continue to expand. Success is based on solid planning, clear communication, and local market expertise.

To join, candidate companies typically send in a company profile, evidence of expertise, and a local market development strategy. Screening confirms partners are prepared for distribution’s rigors from equipment acquisition to establishing reliable supplier connections.

When considering an asphalt production plant, customers often have additional questions and considerations. We have collected some frequently asked questions about asphalt batching plant for sale from our customers. The following are detailed answers to some common questions that will help you make an informed decision.

Asphalt plant closing times are influenced by a combination of variables generally driven by climate and weather, as well as demand from the market. These locations are not year-round operations everywhere. Their hours are typically determined by the weather’s impact on asphalt, safety regulations, and roadwork requirements.

Hot mix asphalt comes out of the plant at high temperatures that are important to both mix quality and efficient use on site. The temperature isn’t merely a statistic; it is fundamental to ensuring the asphalt can be transported, poured, and compacted before it cools. From the plant, the asphalt binders are heated to between 150 and 180 degrees Celsius, or about 300 to 350 degrees Fahrenheit. This is the typical range for the majority of work.

Asphalt plants are facilities that mix, heat and combine raw materials to make the asphalt used in road construction. These plants must juggle resources, control emissions, and maintain the product at optimal temperature while complying with local regulations and shifting weather. The process, while simple in principle, relies on a sequence of steps and equipment operating in unison under close supervision.

An asphalt plant is a plant designed for mixing and producing hot mix asphalt, or HMA, used in roads and other paved surfaces. It combines around 95% stone, sand, or gravel with asphalt cement, a viscous, sticky form of crude oil. This mix needs to be heated, blended, and maintained at specific temperatures for paving.

Asphalt plants don’t operate year round. They shut down for the season when cold and wet weather arrives, which can impact the quality and safety of paving. While when plants close varies geographically, the decision to stop is never arbitrary. It comes from real requirements of the weather, the road, and work rules.

Asphalt plants tend to close during winter in areas where cold temperatures and precipitation create unsafe and ineffective paving conditions. When spring arrives, the decision regarding when to reopen is influenced by the local climate and the requirements of both the plant and the roadwork or construction projects. Most plants in cold climates remain shut down from late fall until mid or late spring, typically from November through March or April.

You can find asphalt plants near you by searching “asphalt plants near me” on Google or in your local business directory, filtering results by location, customer reviews, production capacity, and compliance certifications, and then contacting suppliers to arrange on-site visits.

A hot mix asphalt plant heats aggregate and bitumen to high temperatures (150-180°C) for mixing hot asphalt mix used in permanent road pavements, while a cold mix asphalt plant mixes unheated aggregate with emulsified or cutback bitumen at ambient temperature for temporary repairs, low-traffic roads, or cold-weather construction

Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact Us

WeChat ID: + (86) 15244146667