Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact UsConcrete batching Plant

Are you facing these problems?

1. Supplier quotes consistently exceed expectations.

2. Tight deadlines, and slow progress on design plans and drawings.

3. Limited space, and concerns about unsuitable equipment layout.

4. Concerns about high energy consumption, low output, and substandard accuracy.

5. High equipment failure rate, and significant impact from humidity and temperature.

6. Complex and inconvenient equipment operation.

7. Inconvenient after-sales service, delayed parts delivery, and insufficient spare parts.

8. Concerns about meeting CE/ISO/EAC and other certifications.

9. Concerns about the lack of technical training, installation guidance, and on-site installation services.

10. Questions about equipment customization and multi-purpose customization options.

11. Concerns about compliance with local laws, regulations, and power supply requirements.

12. Long equipment production and transportation cycles.

13. Questions about whether the supplier is a genuine manufacturer and provides excellent service quality?

For the past thirty years, we have exported to over 130 countries and regions and have more than 7,000 partners. We have ample experience and solutions to truly solve your problems. Please tell us your needs, and let’s get started.

Free On-Site Survey

Site Planning

Schematic Diagram Design

Basic Guide

Equipment Installation

Spare Parts Service

Project Transformation

Return on Investment (ROI) Analysis

Local Service Location

Concrete Batching Plant (Fixed Type)

Hot Sale:HZS90 HZS120 HZS180 HZS240

Capacity: 90-240 m³/hour

Mixer: Twin shaft mixer, Planetary

Aggregate Feeder: belt type or hopper type

Application: Large concrete production projects, commercial concrete production

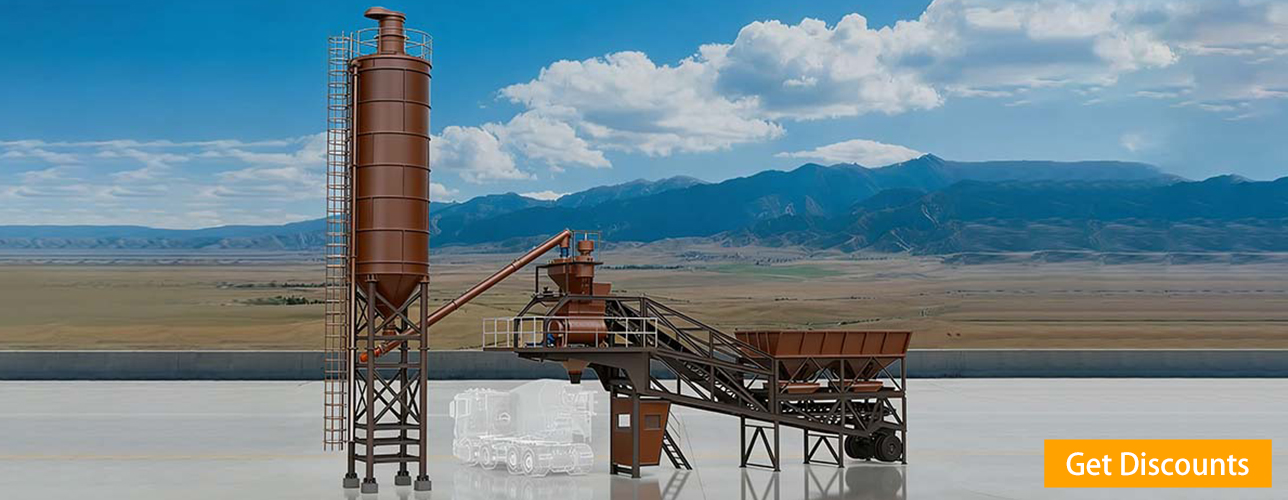

Concrete Batching Plant (Mobile Type)

Hot Sale:MB35 MB50 MB60 MB90

Capacity: 25-90 m³/hour

Mixer: Twin shaft mixer, Planetary

Aggregate Feeder: belt type or hopper type

Application: Small and medium-scale civil engineering construction projects and precast concrete production, and the site needs to be changed frequently.

Aimix Mobile Batching Plant adopts modular design, quick disassembly, easy transition, saving space, low energy consumption, no concrete foundation required, and recommended with horizontal cement silo.

Concrete Batching Plant (Small Type)

Hot Sale:SN25 SN35 SN50

Capacity: 25-50 m³/hour

Mixer: twin shaft mixer

Aggregate Feeder: 2×3.5 m³

Application: Concrete production projects with limited space, civil building construction, precast concrete production

Concrete Batching Plant (HSZ Type)

Hot Sale:HSZ50 HSZ60

Capacity: 50-60 m³/hour

Mixer: twin shaft mixer

Mixing Period: 30 s

Application: Small scale civil engineering construction

Main Configuration

Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact Us

WeChat ID: + (86) 15244146667