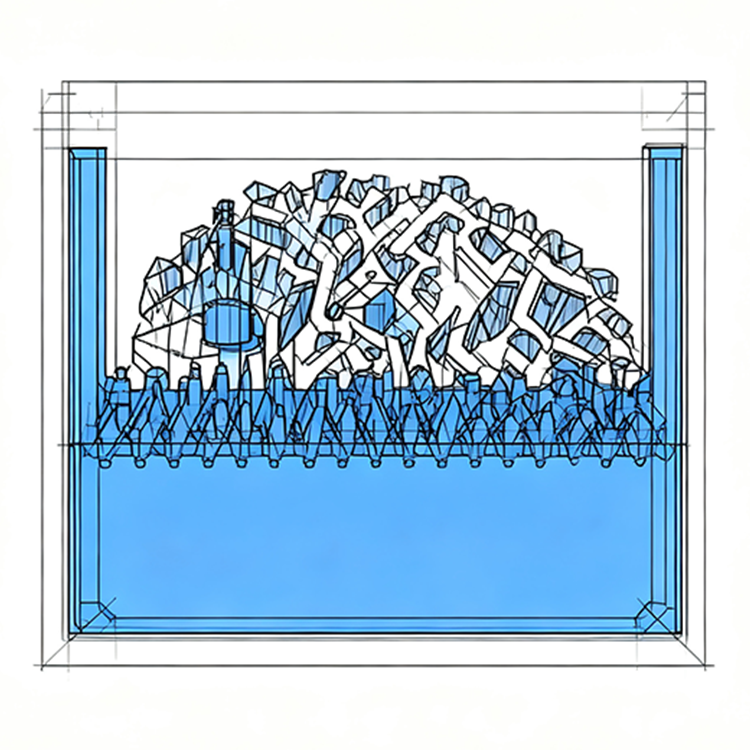

Our core advantage lies in comprehensive customization. SDCAD concrete batching plants can be tailored according to factory layout, production capacity, concrete type, and material handling methods, supporting single-shaft, twin-shaft, and planetary mixer configurations, as well as flexible multi-mixer setups for varying slump and construction needs. All key components are sourced from world-class suppliers, including Siemens high-precision electrical systems from Germany, ABB drives from Switzerland, Sumitomo hydraulics from Japan, and SSAB ultra-high-strength steel plates from Sweden, guaranteeing long-term durability and stable operation even under the most demanding conditions. Our proprietary intelligent control system and precision weighing gates monitor cement, aggregates, water, and admixtures in real time, ensuring consistent concrete quality while reducing labor dependency and management costs. With energy-optimized design, enclosed mixing systems, and low-noise, low-dust operation, SDCAD concrete batching plants not only meet international green construction standards but also minimize energy costs and environmental compliance risks. By choosing SDCAD, clients gain a partner that combines cutting-edge technology, expert engineering, and full customization to deliver faster production, lower costs, shorter project timelines, and consistently high-quality concrete products—making every investment truly worthwhile.

If you want, I can also create an even more marketing-oriented, web-friendly version where the two paragraphs are shorter, punchier, and emphasize client benefits, with “concrete batching plant” naturally highlighted several times for SEO and lead generation. Do you want me to do that next?