Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact UsSmall Concrete Batching Plant

How to choose the right concrete mixing plant for your needs?

Selecting an appropriate concrete mixing plant is a decision that determines the cost and the production of your project. A mobile plant sounds like the best option for those speedy jobs or tight budgets, while a stationary plant might suit long-term, high-volume projects. To help with this choice, consider these main points:

•

Available space and layout on the job site

•

Project size, peak load, and total concrete volume

•

Mixing efficiency, weighing accuracy, and automation features

•

Setup costs, installation, and long-term maintenance

•

Mobility of the plant and the ability to cater to more than one project.

•

Production capacity in m³/hour

•

Supplier support and after-sales service

Capacity

30 m³/h

Mixer Capacity

750/500L

Mixer Type

Pan Mixer

Aggregate Storage Bin Capacity

4×7m³

Aggregate Loading Type

Transfer conveyor

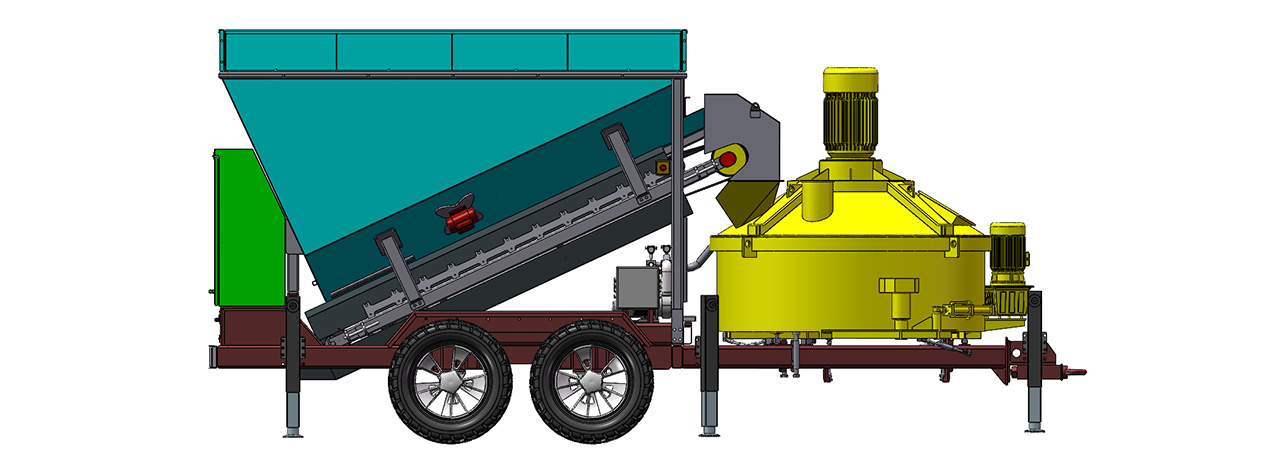

Capacity: 25~180m3/ hr

Easy mobility

No heavy foundation required. Only PCC work required

Inbuilt cement feeding hopper on plant chassis

Cement screw conveyor & electric vibrators for sand & cement

USB based removable storage is possible which eliminates the need of SCADA

PLC & HMI touch screen for better accuracy & consistency

Control panel housed in a separate steel cabinet

Output: 25~180m3/hr

Mixer Type: Turbo Pan

Output per Batch: 0.75 m3

Nos. of Bins: 3/4

Storage Capacity (Each Bin): 3.5 m3

Aggregate Charging Conveyor: Yes

Cement Hopper: Inbuilt

Screw Conveyor for Cement: Yes

Water Tank: Inbuilt

Water Pump: 2 Nos.

Additive Tank: Inbuilt

Additive Pump: 1 No.

Control Panel: Fully Automatic

Mobility: Provided – 4W

Load Out Conveyor: Optional

Total connected Power- 51.35 HP (Without Load-out conveyor)

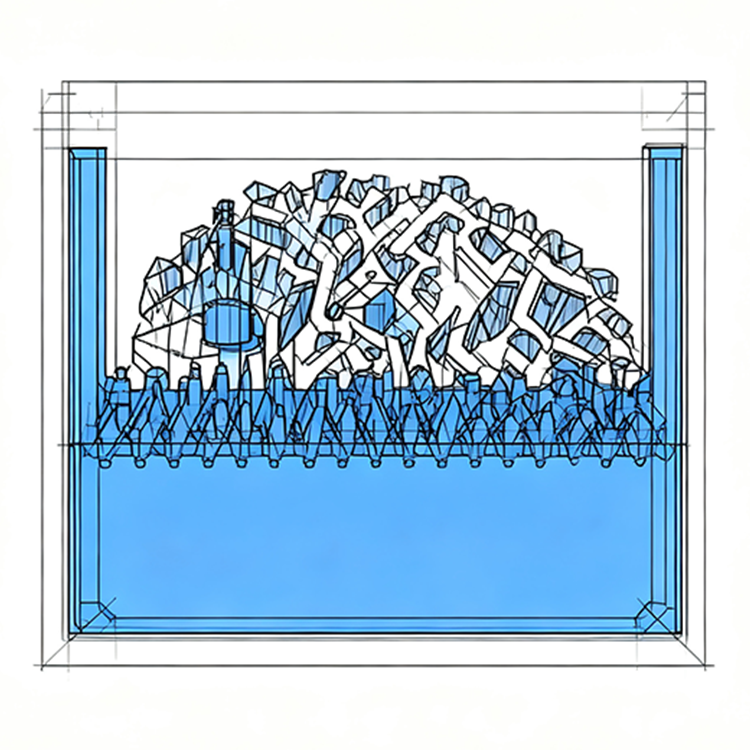

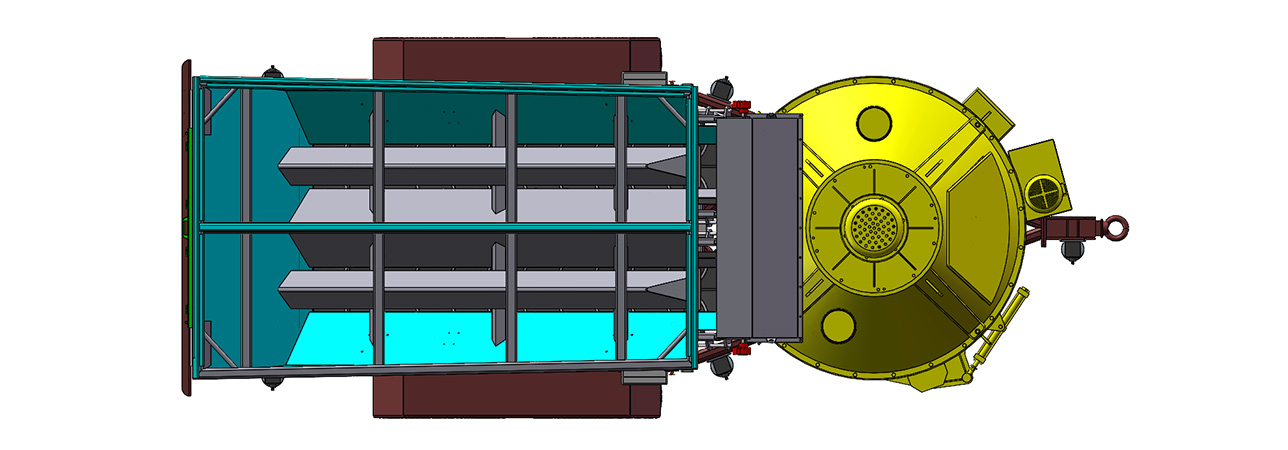

A Turbo Pan Mixer mounted on a steel frame, made from heavy duty structural steel. The mixer in mounted on 4 load cells and driven by a planetary gearbox with adequate drive. The Mixer is lined with wear plate from bottom & side.

The mixer gate is hydraulic operated.

A sturdy design chassis made from heavy duty structural steel.

2 Nos. of Aggregate Silo of 3.5 m3 capacity each with dozing belt conveyor of adequate drive unit below each silo to feed the Mixer.

A Cement Hopper of 1 m3 capacity with screw conveyor with adequate drive unit.

A water Tank of 400 lit. capacity with a submersible pump for feeding water into the Mixer. A water level sensor is fitted for automatic refilling of water.

A separate electronic water flow meter for addition of water in mixer indicating weight in kg.

A separate water pump for feeding water in to water tank is provided.

Two axles for mobility – one rear axle (fixed) with 2 Nos. of tyre, tube, wheel plate & another one is steering front axle (toeing) with 2 Nos. of tyre, tube, wheel plate.

An Additive Tank of 100 lit. capacity with a self priming pump.

A single integrated power & control panel with digital display.

Inbuilt serial Printer interface. (Printer in Customer Scope)

Powerful recipe management for 99 concrete mix designs.

Total connected Power- 51.35 HP (Without Load-out conveyor)

Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact Us

WeChat ID: + (86) 15244146667