Plant Layout & Configuration

The layout of the asphalt mixing plant can be customized according to site size and project requirements, with modular design options allowing flexible arrangement of cold feeders, drying drum, mixing tower, and bitumen tanks in either linear or parallel configurations to optimize efficiency and workflow.

Capacity Range

Production capacity can be tailored from 60 to 400 tons per hour, with adjustable mixer size and drying drum dimensions to match specific production demands for small, medium, or large-scale projects.

Bitumen System Customization

The bitumen system can be designed with horizontal or vertical tanks, various heating methods such as thermal oil, electric, or direct fire, and customizable tank quantity and capacity to suit different production and storage needs.

Dust Collection & Environmental System

The plant can be equipped with single or multi-stage dust collection systems such as bag filters or cyclone separators, with optional secondary dust removal and noise control features to meet international environmental and emission standards.

Control System & Automation

A fully automated PLC control system with touch-screen operation and optional remote monitoring can be provided, featuring customizable software in multiple languages to ensure easy operation and precise control.

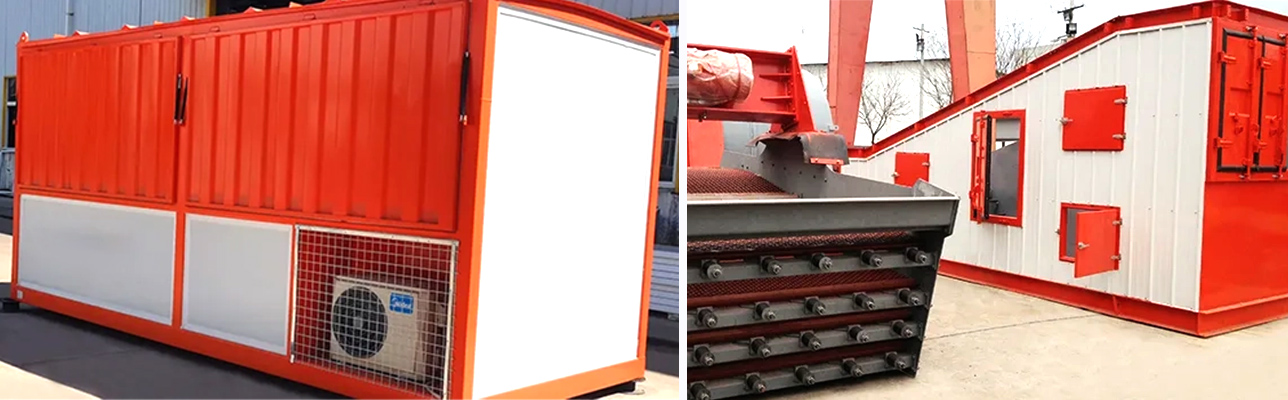

Mobility & Installation Design

Customers can choose between mobile or stationary configurations, with modular structures designed for quick installation, easy relocation, and even foundation-free setup for temporary or frequently moving projects.

Fuel System Options

The burner system can be configured to operate with diesel, heavy oil, natural gas, or coal, offering energy-efficient and environmentally friendly solutions with low fuel consumption and stable combustion performance.

Learn about the main types of Stationary Asphalt Plants:Batch Mix Asphalt Plant&Continuous Mix Asphalt Plant

Batch Mix Asphalt Plant

Core Parameters

- Capacity: 80t/h, 120t/h, 160t/h, 200t/h, 240t/h, 320t/h, 400t/h

- Mixing Accuracy:Aggregate ≤±1%, Asphalt ≤±0.3%

- Mixing Method:Batch mixing, compulsory mixing

- Applicable Mixture:Modified asphalt, colored asphalt, hot mix asphalt(HMA)

- Power:120kW-600kW

- Installation Period:15-30 days

Features

- High mixing accuracy for premium asphalt quality

- Automated control + one-button start = efficient operation

- Remote monitoring reduces downtime and improves reliability

- Ideal for large-scale, high-standard road projects

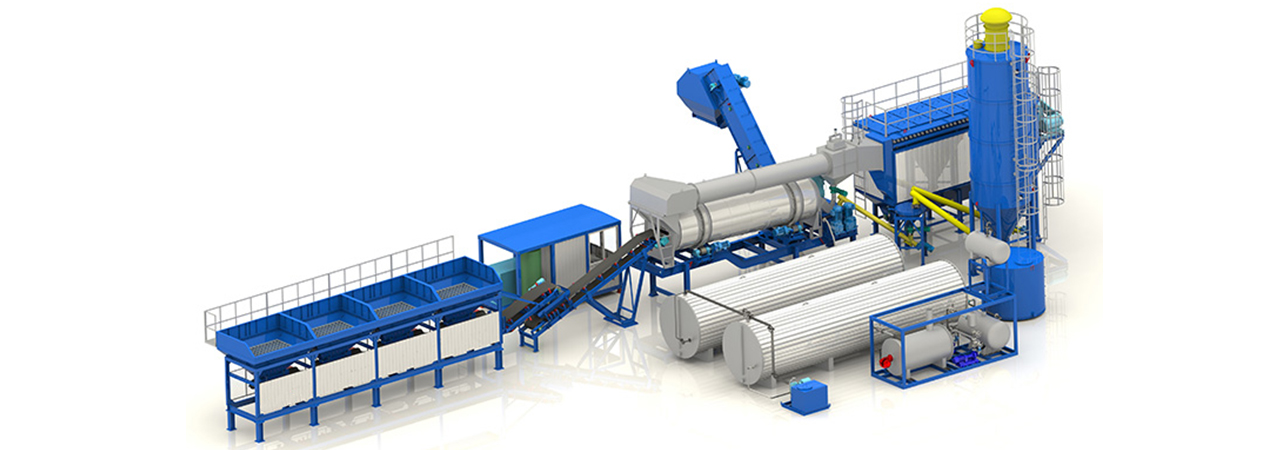

Continuous Mix Asphalt Plant

Core Parameters

- Capacity:100t/h, 200t/h, 300t/h, 500t/h+

- Mixing Accuracy:Aggregate ≤±2%, Asphalt ≤±0.5%

- Mixing Method:Continuous mixing, drum mixing

- Applicable Mixture:Ordinary hot mix asphalt

- Power:100kW-450kW

- Installation Period:10-20 days

Features

- Simple structure, low maintenance cost

- Efficient drying and stable continuous mixing

- Suitable for long-term use in flat, rural job sites

- Great for county roads, small-to-mid volume paving

Main components of a stationary asphalt mixing plant

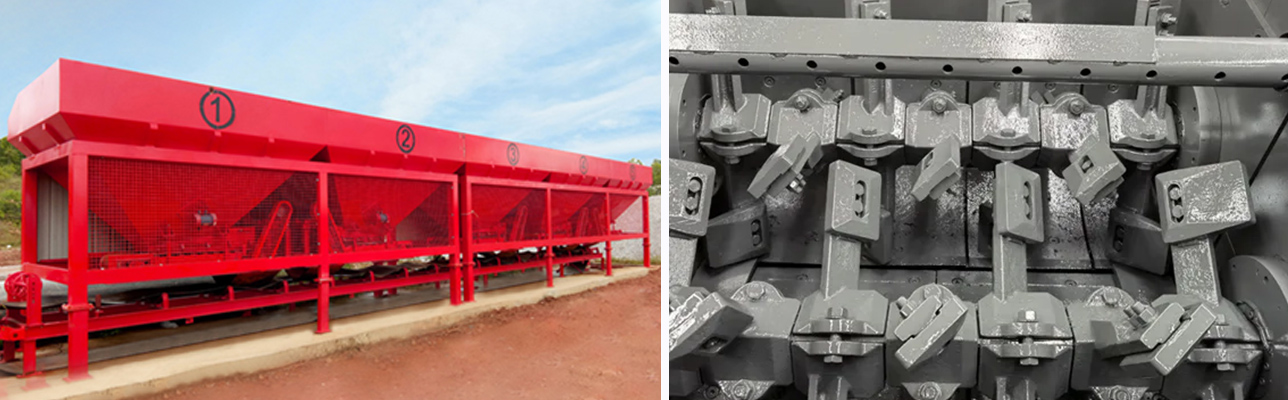

Cold Aggregate Feeding System

- Controlled by frequency converter, feeding smoothly.

- Alarming device for material shortage.

- Adopt seamless belt, long service life.

- Vibrator avoiding the phenomenon of blockage of sand bin.

- Screen with 100 x 100 mm mesh to remove out the over size aggregate.

Mixing System

- Adopting METTLER TOLEDO weighing sensor makes sure accurate weighing, in order to make sure the asphalt mixture quality.

- Adopting FESTO/AIRTAC cylinder and magnetic valve helps working reliably and extending service time and reduce failure ratio.

- Mixer are designed with long arms, shortened shaft diameter and a bi-directional mixing blades array; the mixer discharging process has been completely redesigned, the discharge time is minimal now;

The distance between blades and bottom of the mixer is also restrained to the optimal minimum.

Bitumen Supply System

- The bitumen tank is sturdy and durable.

- Bitumen tanks of different sizes and capacities are available upon request.

- Bitumen tanks are covered with rock wool insulation and galvanized sheets to minimize heat loss.

- The bitumen tanks is heated by a heat conduction oil to ensure the temperature of the bitumen.

Vibrating Screen

- High wear resistance screen (65Mn) with longer working life and lower maintenance cost. The size can be designed according to customers’ requirements.

- Draw and push type of screens are easy and convenient to maintain.

- Types of vibrating screen we can supply: Single-shaft vibration screen, Double-shaft vibration screen and Vibration motor type vibrating screen.

- Rated capacity of our vibrating screen: 40-80t/h with 4 layers, 80-160t/h with 4 layers, 240t/h with 5 layers, 320t/h with 5 or 6 layers, 360t/h and 400t/h with 7 layers, and other customized specifications.

How much does it cost to buy a Stationary Asphalt Mixing Plant?

When choosing an asphalt mixing plant suitable for your project, factors such as type and capacity will influence your decision. At the same time, asphalt plant price is undoubtedly a crucial factor, and knowing the price range plays a vital role in your judgment. Below are the price ranges for two types of mixing plants:

- Stationary Continuous Mix Asphalt Plant: $60,000 – $200,000

- Stationary Asphalt Batch Mix Plant Price : $130,000 – $1,000,000

How to obtain the best value price for a stationary asphalt mixing plant?

- Understand the market supply and demand environment in advance, and try to avoid peak price periods based on the tightness of your own needs.

- Managing the volatility of material prices, such as steel, and choosing to purchase when prices are lower can significantly reduce costs.

- Understanding your own project requirements and choosing the appropriate equipment capacity is crucial to avoid excessive waste or insufficient production capacity.

- Find reliable and reputable local and international manufacturers, conduct factory background checks, and understand the supplier’s situation and product characteristics.

- Consider pricing, shipping costs, and equipment costs comprehensively, as shipping costs are a significant expense.

- Choose reliable suppliers. Reliable suppliers use relatively stable materials, have better technology, and lower failure rates.

- Compare after-sales service; the completeness, timeliness, and level of training provided will also have a strong impact on the added value of later production.

FAQ

What factors affect the cost of an asphalt plant?

Customer-specific design and the location cause a large part of the asphalt plant cost. Additional options and support after the sale can drive up the cost.

How can I reduce asphalt plant costs?

Opt for a manufacturer with factory-direct prices, trusted quality control and turnkey solutions. Purchasing from a reputable dealer brings down long-term costs.

What is included in a turnkey asphalt plant solution?

Turnkey solution includes plant design, manufacturing, installation, training and after-sales service. It guarantees easy installation.

How long does it take to deliver an asphalt plant internationally?

Delivery time varies based on plant size, customization, and destination. The majority of international orders require 30 to 90 days for production and shipping.

Are there different types of asphalt plants available?

Yes, they have stationary, mobile, and bespoke manufacturers. They are ideal for projects of different sizes and engineering requirements.

Does after-sales support affect asphalt plant cost?

Indeed, full after-sales support can increase upfront cost but decrease downtime and maintenance costs in the long run.

Why choose a global asphalt plant supplier?

With a global supplier comes global logistics, in-stock availability and worldwide standards experience. That guarantees dependable supply and stable assistance.