Asphalt plant price: A reasonable price list for 2026

How much does an asphalt mixing plant cost? It’s now 2026, and with global industrialization and the continuous expansion of engineering projects, this is a question many customers want answered. Our asphalt mixing plants range in price from $40,000 to $1 million. The main influencing factors include equipment configuration, production capacity, raw material quality, customization needs, brand, and service. We will provide more information on asphalt mixing plant pricing to better guide your selection.

Price list of different asphalt mixing plants

Different types of asphalt plants have very different prices, so you should choose the right asphalt plant based on your budget and other actual conditions. Below is our asphalt plant price list. The final price will vary depending on whether it is customized and other accessories.

Stationary Asphalt Mixing Plant33

Stationary Asphalt Mixing Plant33 Mobile Asphalt Mixing Plant33

Mobile Asphalt Mixing Plant33 T-type Mobile Batch Mix Plant33

T-type Mobile Batch Mix Plant33 Super Mobile Batch Mix Plant33

Super Mobile Batch Mix Plant33 Super Mobile Drum Mix Plant33

Super Mobile Drum Mix Plant33 Continuous Asphalt Mixing Plant33

Continuous Asphalt Mixing Plant33 Eco-friendly Asphalt Mixing Plant33

Eco-friendly Asphalt Mixing Plant33

Stationary Asphalt Mixing Plant Price

- Capacity: 40~320th

- Mixer Capacity:1000~5000kg.

- Bitumen Aggregate Ratio: 3%-9%.

- Mineral Powder Proportion: 4%-12%

- Stationary Asphalt Batch Mix Plant Price(LB40-LB320): $110,000-$1,000,000

Get Your Custom Quote

Mobile Asphalt Mixing Plant Price

- Capacity:60~160/h

- Mixer Capacity:800-4000kg

- Drying Drum Size:(1500~2600)*(6000~9000)mm

- Fuel Consumption (oil):6-7kg/t

- Mobile Asphalt Batching Plant Price(YLB60-YLBQ160): $170,000-$560,000

Get Your Custom Quote

T-type Mobile Batch Mix Plant Price

- Capacity: 60~200t/h.

- Mixer Capacity: 800~2500kg.

- Fuel Consumption (oil):6.5kg/T.

- Total Power: 154~500kW

- T-type Mobile Batch Mix Plant Price(TLB40-TLB260):$150,000-$760,000

Get Your Custom Quote

Super Mobile Batch Mix Plant Price

- Capacity: 40-90t/h

- No.of Aggregate Bins:2-4

- Movement: Semi-trailer, fully mobile

- Dust Collector: bag-type dust /water dust removal

- Super Mobile Batch Mix Plant Price(SLB40-SLB240):$130,000-$460,000

Get Your Custom Quote

Super Mobile Drum Mix Plant Price

- Capacity:20~200t/h

- Fuel Consumption (oil):7kg/t

- Drying Drum Size:(1200~3800)*(1800~8500)mm

- Filter Area:115-340m2

- Super Mobile Drum Mix Plant Price(SMLB25-SMLB60):$40,000-$70,000

Get Your Custom Quote

Continuous Asphalt Mixing Plant Price

- Capacity:20~200t/h

- Fuel Consumption (oil): 5.5-7kg/t

- Drying Drum Size:(1000~4500)*(1950~9000)mm

- Operation Method: Manual/Semi-automatic

- Continuous Asphalt Mixing Plant Price(CLB25-CLB60):$160,000-$330,000

Get Your Custom Quote

Eco-friendly Asphalt Mixing Plant Price

- Capacity:80~400thMixer

- Capacity:1000~5000kg

- Bitumen Aggregate Ratio: 3%-9%

- Mineral Powder Proportion: 4%-12%

- Eco-friendly Asphalt Mixing Plant Price(EFLB25-EFLB60):$170,000-$1000,000

Get Your Custom Quote

Key Factors Influencing Asphalt Plant Prices

Factors affecting asphalt mixing plants themselves

- Capacity: The price difference between a 30-ton/hour capacity plant and a 200-ton/hour capacity plant can be significant, sometimes several times or even ten times.

- Model Configuration: For example, the price difference between a fixed plant and a mobile plant will also be different.

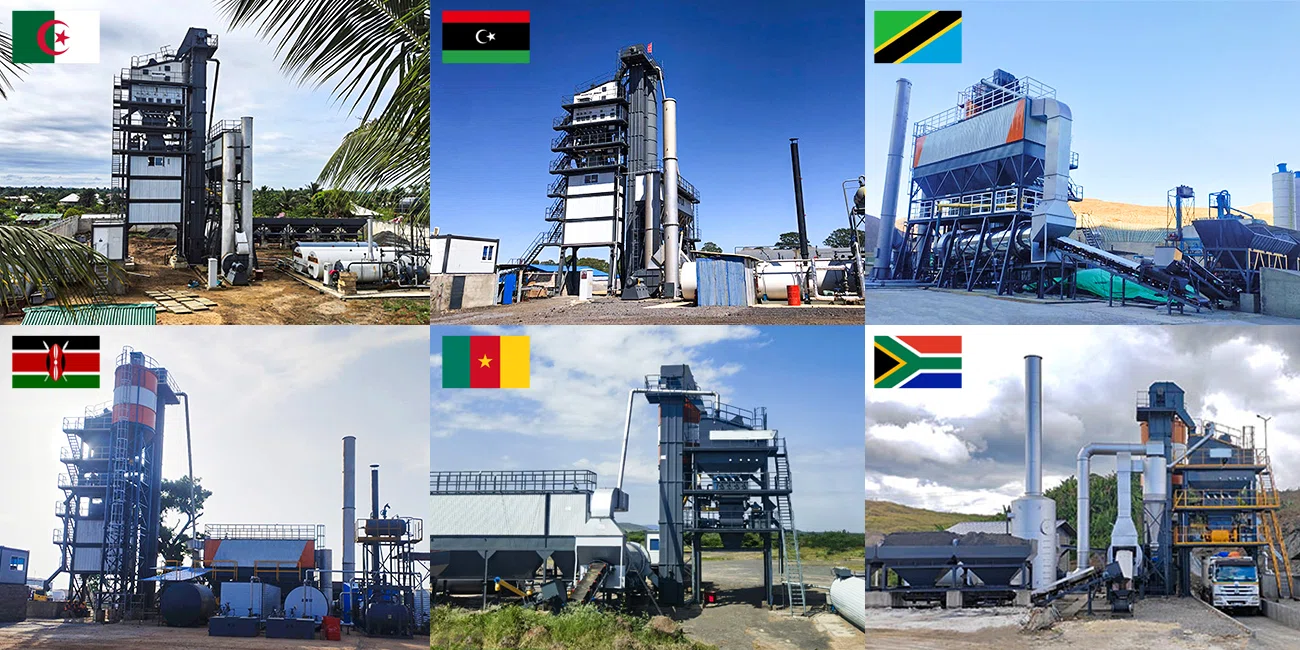

- Brand Reputation and Equipment Quality: For example, high-end brands like CAD use high-quality parts and components, resulting in a higher price but a longer service life.

Relevant service factors:

- Whether technical services, training, and after-sales service are provided:These agreements will have a significant impact on subsequent costs; good cooperation agreements can save a lot of money.

- Shipping costs and installation:A well-designed, modular production system can save on the number of containers, which is crucial, as shipping costs are undoubtedly a significant expense. Installation costs are settled based on local labor costs, so training and guidance are essential.

Other Influencing Factors

- Exchange rate fluctuations: Exchange rate fluctuations have a significant short-term impact on equipment, potentially causing a difference of several percentage points.

- Supply of raw materials such as steel: Significant increases or decreases in raw material prices greatly affect the price of asphalt mixing plants. Therefore, choosing an appropriate time to purchase can save substantial costs.

- Local import tax policies and government environmental requirements: Different tariffs imposed by importing and exporting countries can lead to significant differences in procurement costs, which in turn affect prices.

Obtain a satisfactory asphalt plant price while ensuring quality

We already know that many factors influence the price of asphalt mixing plants. Therefore, there are also many details to pay attention to when purchasing an asphalt mixing plant to reduce costs. Carefully attending to these details can save us at least 20% of the cost. Let’s examine them in detail below:

- Choose a reliable manufacturer: A reliable and professional supplier will provide more reasonable suggestions based on your needs, allowing you to achieve results beyond your expectations.

- Compare quotes from multiple factories: Send numerous inquiries to multiple suppliers. During the quoting process, understand the sales staff’s service attitude, design capabilities, and responsiveness. Then, comprehensively consider the quotes and choose the one that best suits your needs.

- Consider your own project requirements: Based on your actual needs, understand that what suits you best is the best. Avoid over-purchasing. Plan comprehensively according to the lifecycle of your project to avoid waste or failure to meet your needs, resulting in unnecessary losses.

- Improve your negotiation skills: When receiving quotes, carefully review them and then negotiate to ensure that the price of the purchased asphalt mixing plant is within your expectations.

- High-quality components: Choosing high-quality asphalt mixing plant components will significantly reduce the failure rate and improve production efficiency, undoubtedly a practical way to reduce costs.

- Train good operators: A good operator can improve the overall operating efficiency of the mixing plant, solve many unforeseen problems, ensure safe and uninterrupted operation, and also reduce costs.

- Strive for more rights and services: For example, request more training and construction guidance, installment payment plans, and other terms that are favorable to you.

- From a practical standpoint: Stable production is the primary goal. While excessive automation is good, you must be discerning. Simple and efficient production is best. Don’t deliberately pursue high-tech automation; choose selectively.

- Effective and timely maintenance: Regular maintenance prevents malfunctions during operation, reduces losses, and improves efficiency.

Besides the best asphalt plant price, what other services can we provide?

While ensuring the most favorable prices for our customers, SDCAD always treats their projects as its own, consistently providing highly competitive services: A streamlined sales process to contract signing: rapid quotation, patient communication, and design. Active cooperation with factory inspections: As a leading asphalt mixing plant manufacturer in China, we welcome customers worldwide to conduct factory inspections and negotiations. Pre-shipment trial operation: Trial operation is conducted before shipment to ensure the product is free of any issues. Video monitoring of production: Production progress can be monitored at any time via video. Operator training and on-site construction guidance: Hands-on training enables operators to master operating techniques and improve efficiency. Global spare parts and after-sales service: The most timely delivery methods and multiple service stations significantly reduce the time required for parts replacement.

CONTACT US

If you have any questions, feedback, suggestions, or other assistance,please fill out the form below.

We need to know several things:

1. List the specific equipment or its type (e.g., asphalt mixing plant, batchingplant, self-loading mixer, concrete pump, crushing plant, etc.).

2. Output capacity (m3, tons/hour)? Product model?

3. Project start time? Project duration?

4. Is it a tender project or an in-house project?

5. Project type (e.g., building a house, factory, road, bridge, dam, airport,etc.).