1. The Shift in Global Concrete Production Dynamics

In recent years, the construction industry has undergone a dramatic transformation. Traditional fixed batching setups are being replaced by more adaptive solutions—most notably, the mobile concrete batching plant and modular concrete batching plant. The shift isn’t just technological; it’s a strategic response to evolving project requirements, environmental regulations, and the global demand for faster, more cost-efficient operations.

According to data from international infrastructure organizations, more than 60% of mid- to large-scale projects in developing regions now utilize mobile or semi-mobile batching systems. The reason is clear: flexibility, precision, and mobility now define productivity.

Notably, global contractors are increasingly turning to stationary concrete batching plant systems for centralized production and mobile concrete batching plant models for rapid deployment. This duality enables companies to maintain consistent mix quality across dispersed project sites.

2. The Economic and Operational Advantages

2.1 Cost Efficiency and ROI

One of the core reasons behind the rising adoption of modular concrete plants is their exceptional cost-effectiveness. Traditional plants require extensive civil foundations, long installation times, and permanent structures. In contrast, modular plants are pre-assembled, transportable, and can be installed in less than 10 days.

A typical concrete batching plant cost ranges from $60,000 to $250,000, depending on configuration and capacity. However, when analyzed over a 5-year operational cycle, modular and mobile units offer up to 30% lower total lifecycle costs due to reduced relocation expenses, quicker setup, and minimal downtime.

Interestingly, even dry mix mortar plant setups—originally designed for stationary use—are being re-engineered into modular forms to meet rapid production needs on infrastructure and road projects.

2.2 Reduced Downtime and Simplified Logistics

A major challenge in traditional systems is downtime during setup or maintenance. Modular solutions address this with standardized panels, plug-and-play electrical systems, and easily replaceable concrete batching plant parts. For companies managing projects across borders, this can mean uninterrupted operations even when relocating between countries.

Moreover, the use of volumetric concrete batching plant models allows for real-time mix adjustment, cutting waste by up to 20% and enabling precise ratio calibration on demand.

3. Technological Integration and Automation

3.1 Digital Control and Precision Management

Modern concrete batching plant control panel systems have evolved beyond manual calibration. AI-enabled interfaces, automated moisture sensors, and real-time weighing systems ensure accuracy within ±1% of target mix ratios.

With concrete batch plant software, operators can monitor multiple sites remotely, predict material shortages, and generate automated reports for compliance documentation. This degree of automation reduces labor dependency by up to 40% while enhancing data accuracy and safety monitoring.

3.2 Predictive Maintenance and Data Analytics

Predictive algorithms are increasingly embedded in concrete mixing plant equipment, allowing early detection of mechanical issues. For instance, vibration analysis and power load sensors can anticipate mixer motor failures weeks in advance. This proactive maintenance model has been shown to reduce unscheduled downtime by 25–30%, directly impacting ROI.

4. Environmental and Regulatory Compliance

Sustainability is no longer optional. Governments across Asia, Europe, and North America are mandating stricter environmental compliance for all industrial equipment—including concrete mixing plants.

4.1 Dust and Noise Control

Modern precast concrete batching plant designs incorporate enclosed aggregate feeding systems and dust collection filters that capture up to 99% of particulate emissions. These designs comply with ISO 14001 and local emission standards, ensuring minimal air pollution on construction sites.

4.2 Water Recycling and Energy Efficiency

Effluent water from cleaning mixers and aggregates is fully recyclable in the latest dry concrete batching plant configurations. Additionally, energy-efficient motors and intelligent mixing algorithms have cut average power consumption by 15–20% in large stationary concrete batching plant setups.

Interestingly, many modular systems integrate solar-assisted energy systems, making them a step closer to carbon-neutral concrete production.

5. Global Supply Chain and Manufacturing Trends

China, in particular, has emerged as the hub for concrete batching plant manufacturers. Leading concrete batching plant manufacturers in China are now exporting modular units to over 100 countries, offering both OEM and customized systems that comply with CE, ISO, and EPA standards.

The integration of standardized design frameworks—such as concrete batching plant layout drawing PDF templates—has significantly shortened the engineering cycle. This allows rapid customization while maintaining global quality assurance benchmarks.

For international contractors, this supply chain maturity translates into shorter lead times, better spare parts availability, and lower maintenance risks.

6. Design Optimization and Production Flow

6.1 Layout Efficiency

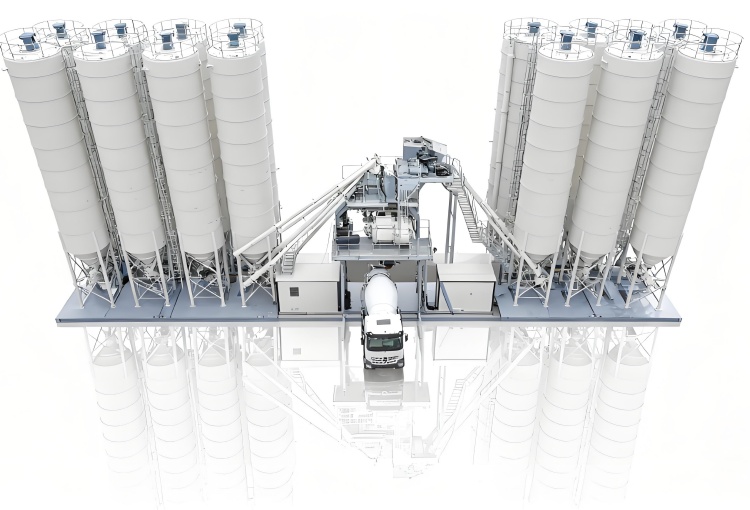

An optimized concrete batching plant layout enhances productivity and safety simultaneously. In modular systems, the linear alignment of aggregate storage, mixing, and discharge points minimizes conveyor length, reducing power consumption by 10–12%.

A typical 120 m³/h modular batching setup occupies 40% less space compared to traditional designs, making it ideal for dense urban or temporary construction sites.

6.2 Flexibility in Project Types

From highways and bridges to offshore foundations, mobile and modular setups can be adapted for every scenario. The grout batching plant variant, for instance, is used in tunneling and foundation works, offering on-site high-density grout mixes with immediate placement capability.

Meanwhile, compact units such as concrete batching plant mini systems cater to small projects or remote rural developments where space and logistics are limited.

7. Cost Structure and Performance Benchmarking

To evaluate total cost performance, experts often compare concrete batching plant price against productivity metrics like cubic meters per labor hour. Modular and mobile systems consistently outperform traditional setups, offering 20–25% better production efficiency at comparable energy costs.

Additionally, the concrete mixing plant cost analysis indicates that transportation and setup form the largest variable expenses. Reducing these through modular design contributes directly to profit margins.

Long-term, the return on investment (ROI) from modularization can reach up to 45% within the first 24 months, depending on utilization rates and maintenance practices.

8. Standardization and Quality Assurance

A defining factor in modern batching plant technology is the adoption of standardized calibration and testing systems. Concrete batching plant calibration now follows globally recognized ISO/ASTM protocols, ensuring consistent mix quality regardless of geography or weather variations.

Advanced plants can self-adjust based on real-time temperature and humidity inputs, preserving compressive strength uniformity even under extreme climate fluctuations.

Furthermore, quality audits backed by digital logs and concrete batching plant diagram models help plant managers identify performance deviations early—enhancing reliability and regulatory transparency.

9. Long-Term Optimization Strategies

While the initial benefits of modular and mobile systems are clear, long-term competitiveness depends on continuous optimization. Key areas include:

-

Automation Expansion – Integrate AI-driven scheduling across ready mix concrete plant fleets for better delivery synchronization.

-

Lifecycle Management – Adopt condition-based maintenance frameworks to minimize spare parts consumption and extend operational lifespan.

-

Sustainability Reporting – Track CO₂ savings from ready mix concrete plant layout improvements to strengthen ESG credentials.

-

Global Scalability – Use standardized concrete mixing batching plant modules for rapid deployment across multiple countries.

By systematically implementing these strategies, contractors can maintain cost stability even amid volatile global material markets.

10. The Future Outlook: Smart, Modular, and Connected

The next generation of concrete batching plant manufacturers is focusing on digital integration, modular robotics, and decentralized control systems. Plants will soon communicate directly with supply networks, adjusting cement procurement or aggregate mixing automatically based on project demands.

In fact, experts predict that by 2030, over 75% of all new concrete batching plants will be modular or mobile in structure, redefining how the construction world perceives flexibility and efficiency.

Conclusion

The dominance of modular and mobile concrete batching plants is no coincidence. It reflects an industry-wide recognition that adaptability, speed, and sustainability are the future pillars of construction technology.

Whether it’s a precast concrete batching plant for industrial projects or a mobile concrete batching plant for rapid infrastructure deployment, the modular revolution is reshaping how concrete is produced worldwide.

Companies embracing this transformation are not just optimizing production—they are redefining what it means to build efficiently in the 21st century.