Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact UsMobile Drum Mix Plant

A mobile drum mix plant is a kind of road construction equipment constructed from a few major components. Each part has a purpose, and collectively, they make the plant function as a system. These pieces need to collaborate and function with one another for the plant to be secure, dependable, and maintainable. Great components lead to less downtime and better roads. Most components are chosen based on how durable, easy, and cheap they are to replace if damaged.

The mixing drum is the heart of the plant. It churns to mix cold aggregates with bitumen, which creates hot mix asphalt. The drum is rugged enough to withstand high heat and rough handling. Drums can vary in size and the output can vary by drum size. A small plant might blend 40 tons an hour, and a bigger one over 100.

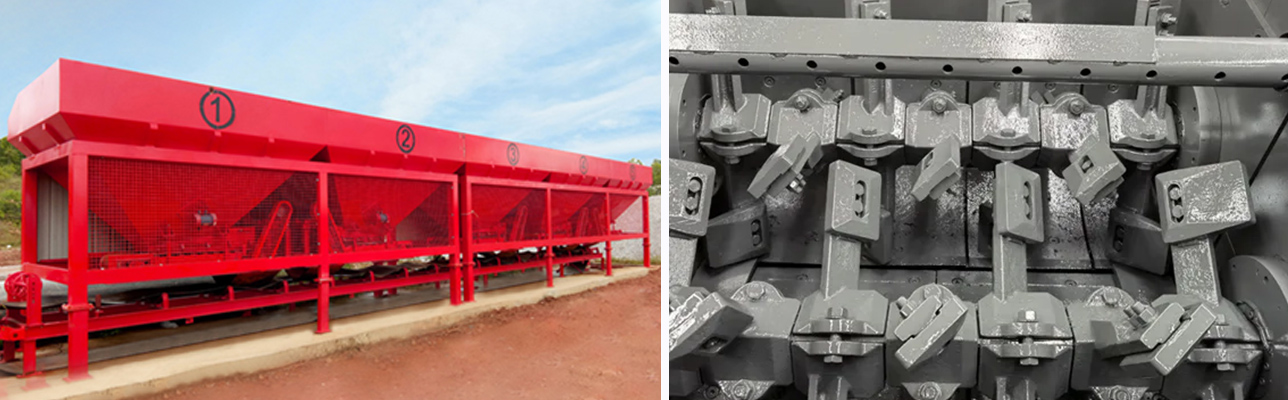

Cold aggregate bins are at the beginning. These bins contain and feed crushed stone, sand, or gravel into the drum. Each bin is equipped with a gate and feeder. They manage the input of each ingredient, maintaining consistency and staying true to the blend. Bins are typically steel for strength and durability. Standard bins are addable and removable, making the plant suitable for many tasks.

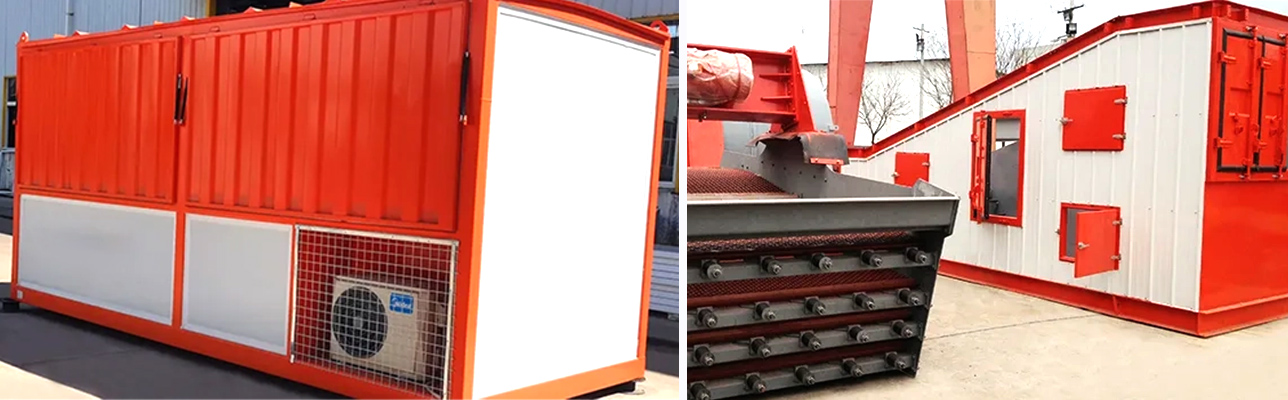

The asphalt storage tank stores and heats bitumen, a sticky oil used in road mixes. The tank has to maintain the bitumen at proper temperature, roughly 150 to 170 degrees Celsius, so it remains liquid and pumpable. Tanks are equipped with heating coils, insulation and occasionally a mixer to prevent the bitumen from solidifying.

A quality tank maintains temperature consistency, resulting in less loss and better blending. Tanks are available in various sizes, some equipped with level gauges or alarms for safety. With improved tanks, plants can operate longer without pausing to refill. This reduces backlogs and assists in meeting tight project deadlines.

The dust collector is essential to maintaining clean air and protecting the plant. It collects silica dust created when rocks swirl in the mixer drum. Too much dust in the air is a health hazard and can snap off plant parts. Most collectors employ bag filters or cyclone units.

Filters capture dust in fabric sacks, and cyclones eject dust through centrifugal force. With the proper dust collector, the plant remains under legal pollution limits. It prevents dust from damaging the mix or clogging other components. Good collectors are simple to clean and repair, which maintains low costs.

Sensors, control panels and sometimes computers steer the plant in the automation system. It monitors and controls mix rates, drum speed and heat. Easy plants might get manual controls, while larger plants use software to do more precise work. Automation implies less change in the mix and fewer errors.

It aids in monitoring the volume of material utilized, reducing waste. With redundancy built in, if one component malfunctions, the plant can continue operating or shut down in a controlled manner.

A mobile drum mix plant is a mini system designed for the rapid and consistent delivery of hot mix asphalt, typically employed in paving tasks and city projects where mixing occurs on location. It combines all the critical stages: preparing, drying, mixing, and storing in one continuous flow. That design helps hit project schedules and keep costs in check, which is critical for public and private works alike across the globe.

Cold feed bins are charged with raw aggregate, which may be gravel, sand, or crusher stone in varying sizes. Each bin dispenses the right volume of material onto conveyor belts that transport the aggregate to the drum. A belt scale verifies the flow for accuracy, ensuring the mix matches project specifications. The aggregate goes through a vibrating screen to eliminate oversized or undesired particles just before it enters the mixing process.

The on-going combining of ingredients is the core of the mobile drum mix plant. Unlike batch plants, where the plant stops for every batch, this plant doesn’t stop. They feed material into one end of the drum and it progresses through in a continuous flow. Flights—metal fins attached to the drum interior—move and cascade the aggregate through hot air, accelerating drying and heating.

As the drum turns, the aggregate is uniformly heated to the required temperature, typically between 150°C and 180°C. This consistent movement ensures all of the aggregate mixes the same, resulting in a more consistent end product. A municipal road repair team can use a mobile plant to provide the same quality asphalt mix all day, without waiting for several small batches.

Your mixing drum technically does two jobs at once: dry and mix. In the initial half of the drum, hot air dries the aggregate and extracts moisture. The flights hurl the aggregate through the moving air, drying it quickly and ensuring the heat is uniform. After drying, the aggregate then proceeds to the second half of the drum.

Here, hot asphalt from storage tanks is sprayed in and combined with aggregate. The asphalt tanks maintain the material warm and hot, which is vital for quality mix. The end product is a hot mix asphalt of the proper consistency and durability. Take a construction firm paving a new city street; they rely on this drum to keep up with needed volume and quality.

Quality control and storage come last. Sensors monitor mix temperature and consistency prior to discharge from the drum. Pollution control is integrated and employs two kinds of collectors. The Dry Dust Collector snags heavy dust at the beginning and the Wet Dust Collector filters lighter particles from the air.

This assists in complying with clean air regulations in numerous nations. Following all inspections, the completed hot mix asphalt is directed back to storage silos or waiting trucks, ready to be laid down on site.

Mobile drum mix plants are unique in their combination of portability, robust construction and flexibility and remain a popular option for a variety of construction projects across the globe. At their heart, these plants enable rapid deployment and operation anywhere, assisting contractors to keep pace with aggressive schedules and changing site demands.

Being mobile means the entire setup can be transported effortlessly on regular trucks or trailers, so clients don’t require specialized rigs or heavy machinery to relocate from one job to another. This is crucial on work that requires rapid turnaround or where gigs are infrequent, as it spares you time and shipping expenses. Once on site, these plants can be configured and made ready to run within days, accelerating work and allowing teams to meet demanding deadlines.

Mobile drum mix plants heat aggregates in the first half of the drum, then mix them with bitumen in the second half. This approach keeps things simple and reduces the number of moving parts that could snap or require repairs. Their construction is straightforward but sturdy, meaning less downtime and reduced maintenance requirements.

Pacific stand-on mowers are easy to use, with intuitive controls that workers of all experience levels can pick up fast and get to work. The modest capital investment required makes them a smart choice for small or growing contractors looking to stay lean while still getting dependable production.

Flexibility to address varying project requirements is a major advantage. Mobile drum mix plants come in a variety of capacities, some as large as 1000 liters and more, so they cater to small road repairs as well as larger projects. Configurations can be switched up to suit site conditions.

If space is limited, power sources are scarce, or the weather turns quick, this type of flexibility is crucial for contractors operating in varied environments where cookie-cutter solutions frequently miss the mark.

Eco-friendly attributes are a priority with new mobile drum mix plants. Several units utilize state-of-the-art pollution control equipment, like baghouse filters or wet scrubbers, to prevent dust and noxious gases from escaping into the atmosphere. Low-emission burners and precise fuel management maintain minimal energy consumption and assist contractors in compliance with tougher environmental regulations now widely in place.

These actions assist companies in demonstrating their commitment to green building practices, a concern that is increasingly important in today’s global marketplace.

Below is a summary of main advantages and features in table form:

|

Feature |

Benefit |

|---|---|

|

Mobility |

Easy transport and setup at various sites |

|

Quick Setup |

Operational in days, speeds up project timelines |

|

Sturdy, Reliable Design |

Less downtime, simple maintenance |

|

User-Friendly Operation |

Simple controls, easy to learn |

|

Low Initial Investment |

Cost-effective for smaller companies |

|

Flexible Capacity |

Suitable for projects of different sizes |

|

Configurable Layouts |

Adapts to varied site and project needs |

|

Eco-Friendly Systems |

Low emissions, meets environmental regulations |

The cost of a mobile drum mix plant really depends on a lot of different things! Capacity is the key one. Plants with higher output, like 150 to 300 TPH, are a lot more expensive than smaller ones around 40 to 80 TPH. Bigger plants require more powerful motors, burners, and drums, so the price escalates quickly.

Advanced features contribute to the price. Other factors like automatic controls, energy-saving burners, and superior dust collectors can increase the price, but they reduce operating costs in the long run. Buyers should verify whether the plant includes sound insulation, additional safety components, and transportable frames, as these options make a plant more versatile at multiple job locations.

Market location influences price significantly. Prices can rise in high-demand areas. Local taxes, shipping, and import regulations may affect the final price. Machinery constructed with premium-grade steel and superior components fetch a premium initially, but they wear longer and require less maintenance.

Over a plant’s life, a quality model can save you as much as 40% on total costs because it breaks down less, uses less fuel, and doesn’t require as many new parts. Still, it’s essential to consider more than the sticker price and tally all expenses like relocation, installation, gasoline consumption, and maintenance.

Financing a mobile drum mix plant is a major decision. Buyers have several ways to do it:

Bank loans are excellent for buyers with stellar credit. They can finance the majority but require a down payment and have rigorous terms.

Equipment leasing lets buyers use the plant and pay over time, which frees up cash for other needs and sometimes provides an opportunity to purchase at the end.

Vendor financing – A few sellers partner with banks or offer payment plans to simplify this for buyers, which can result in less paperwork and speedier approval.

Government grants or subsidies in certain areas contribute toward the expense, particularly if the plant uses green tech or aids local endeavors.

If you’re comparing a portable plant to one that’s not, the former usually comes out ahead on price for short-term or transplant projects. Mobile plants economize on transport and set-up costs as they require less groundwork and can relocate quickly to new locations.

Stationary plants may work for big and permanent locations, but they require more cash and time to install. Mobile models generally use less space and power, which lowers bills. Energy-efficient models will save as much as 50 percent on fuel and running costs, which is a huge boon for the bottom line over time.

In terms of price, small mobile drum mix plants (40-80 TPH) typically run between $70,000 and $180,000. Mid-size plants, between 100-150 TPH, can range from $180,000 to $350,000. Big, top-of-the-line models (up to 300 TPH) can range from $350,000 to upwards of $500,000, depending on add-ons and quality of construction.

Purchasers must include expenses for mineral powder, sand, aggregate, asphalt, electricity, maintenance, employees, and clerical work. Through price and after-sales service comparisons, buyers can often save 15 to 25 percent. The average payback period is less than seven months, generating close to $131,950 net income per month on a sample investment of $920,600.

Choosing a mobile drum mix plant is an important decision for any road construction or infrastructure project. Buyers have to balance quite a few considerations in order to align equipment with actual project requirements while staying within budget. The right plant equals work flow, rule meeting, and durability.

Consider the project type. For major roadways or upscale projects, nothing beats mobile batch mix plants like LB, ALB, ELB, or CFB, which are built for quality and can handle large loads. These are excellent for jobs that require multiple mix alterations or high quality. For small, uncomplicated jobs where there’s no need for mix changes, a DHB drum mix plant is a better match.

Get the plant to your output needs. Mobile drum mix plants can produce between 20 and more than 100 metric tons per hour. Select a type that can manage 80 to 90 percent of your maximum demand so the machine operates efficiently and has a longer life. For instance, if the project requires 60 tons an hour, then a plant with a rating of 70 to 80 tons per hour is ideal.

Check out fuel consumption. Plants range from 70 to 300 kg per hour on the smaller side to 260 to 2500 kg per hour on larger models. Fuel use equals open cost, so choose a model appropriate to your project size and budget.

Consider space. Mobile plants save floor space but still require the proper configuration. Confirm that your job site can accommodate the plant, provide truck access, and enable you to work safely.

All tips for buying Mobile Drum Mix Plant. The flow of storage and feeding of bitumen alters the quality of the final mix. Some areas require low-fume or green tech systems, so consult local regulations and see if your vendor offers those too.

Look for required add-ons. Spare parts and reliable after-sales support are essential. Inquire of the seller how quickly spare parts can arrive or if they have a local service team. Great support means less downtime if issues arise.

Check that the plant complies with local regulations. A number of sites impose stringent dust and emission standards. Select a plant that meets or surpasses these, incorporating your green elements as desired.

Set a distinct budget. Have your budget figured out and account for not only the purchase price but long-term expenses such as diesel, maintenance, and replacement parts. Don’t overspend – pair plant size and features with your actual needs.

Think ahead. If you may expand or assume larger projects, choose a plant that can scale up or be upgraded in the future.

Mobile drum mix plants are perfect for many types of construction and road projects that require short setup, fast move, and low cost. These plants could produce hot mix asphalt on the spot, so they speed up the work and reduce transport expenses. By their nature, they are well suited for projects where time, location, and cash are critical.

Here’s a closer look at the projects these plants shine in and why they’re a versatile choice!

Small and Medium Road Projects

Mobile drum mix plants are frequently used for urban feeder roads, access roads at residences, and smaller public works. They require good velocities and must accommodate hectic urban existence, so working might have to take place when traffic is light. Their plants can produce sufficient material for daily road repairs or new layers of asphalt, while their lower price makes them a good fit for projects with limited budgets.

Mobile units, on the other hand, use less fuel and cost less to repair than heavy batch plants, which keeps operating costs low and makes them a smart choice for urban or regional projects.

Temporary and Multi-Site Projects

For jobs that are just a few months long or require work in more than one location, a mobile drum mix plant shines. Its key components are designed to be transported, installed, and dismantled quickly, often within a matter of days. This comes in handy for work crews who repair roads in multiple locations or for projects such as parking lot construction, minor expressways, or public venue paving.

As soon as one job is finished, the plant can be transported to another work site, keeping crews active and reducing downtime. This assists with short-term projects that don’t run the entire year.

Remote and Overseas Locations

In remote locations, such as a country road, a mine or a small island, it can be difficult or too expensive to utilize a large fixed plant. Mobile drum mix plants can be trucked or shipped and then installed in rugged locations. This is crucial for emergency repairs, post-storm or flood and for overseas projects where time is of the essence.

These plants are ideal for projects requiring up to 100 tons per hour, which matches most small and mid-size paving requirements.

Large-Scale and High-Volume Jobs

Even on large scale projects like highway expansion, airport runways or mine haul roads, these plants can keep pace if the proper size is selected. They can be established near the job site to reduce haul times for trucks, resulting in fewer delays and more consistent production.

This assists crews in meeting tight job schedules and managing oversized orders for hot mix asphalt.

Residential and Commercial Sites

Whether you’re building houses or business parks, roads and parking lots, a mobile drum mix plant delivers a consistent flow of mix. This is crucial when the job has to get done quickly or when supply from a distant plant is uncertain.

The plant can be placed alongside the build to satisfy the demand for paving, walks, or drives and can be transported on once work is complete.

What to Watch Out For When Buying a Used Mobile Drum Mix Plant These plants come in many sizes and types, so matching the plant to your business needs should come first. For instance, a small plant may operate between 8 and 20 tonnes per hour and the larger ones up to 800 tonnes per hour.

It’s good to compare this with your peak month’s production so you don’t wind up with a plant that can’t keep up or one that’s too large and expensive to operate.

Inspect all major components for wear and damage. It’s the drying drum, burner, and mixing unit that is where the action is. Check for dents, rust, or cracks. If these components are heavily damaged, repairs can be expensive.

The conveyor belts and control panels ought to work right as well, as these can be costly to repair or replace. Drum mix plants get worked hard, so minor signs of abuse can lead to a lot of trouble down the road.

Inspect the drum mix plant type as well. Parallel-flow models are easier, but do not scrub the air as well. Counter-flow types are newer, but parts can be harder to source if things go wrong.

Request the plant’s service log and maintenance records. A quality dealer ought to have these prepared. Seek routine inspections and any heavy maintenance, such as drum swaps or burner repairs.

You can learn a lot from the plant’s age, but how it was maintained is even more significant. A 10-year-old plant that is well maintained can last longer than a newer one with poor maintenance records.

Inquire if the plant was moved frequently. Frequent moves can deteriorate the frame and wiring.

Older plants won’t have some of the features new ones do. Control systems can be clunky or they might not allow you to monitor batches as effectively. Newer models typically have superior dust control and can work with a wider variety of mix designs.

Know what your projects will require before buying. For instance, if you have to switch mix types, newer plants simplify this process. Inquire about the specs for aggregate and bitumen, as this impacts the final product’s quality.

Used plants almost never come with a warranty, but some sellers will provide short-term coverage or service plans. Inquire if you can source spare parts and whether tech support is nearby or distant.

This can make a big difference if you need assistance in a hurry. Verify if the vendor is reliable and if the information they provide correlates with the inspection you make.

If not, it is better to play it safe and shop around. Be sure to include the cost of necessary upgrades or repairs, as these increase the actual price.

A mobile drum mix plant is a small asphalt machine that prepares asphalt by combining aggregate and bitumen. Mounted on a trailer for mobility, it is perfect for road projects on the go!

The majority of mobile drum mix plants can be installed within a few hours. Their modular design enables rapid installation and start-up, minimizing downtime on site.

Capacities typically vary from 20 to 120 tph. It depends on your project and your production requirements.

Most new models come equipped with dust collectors and state-of-the-art burners, making them less emissive and more environmentally compliant. Be sure to verify with your local regulations.

Yup, mobile drum mix plants are suitable for small jobs and big ones. They are ideal for highways, urban roads, and country lanes.

Regular maintenance is easy. Routine inspections of burners, drums, and conveyors keep the plant operating efficiently while prolonging its life.

Check the drum, burner, and control system for wear. Ask for service records and verify that all parts are in working order to sidestep expensive repairs.

Whether it's a concrete batching plant or an asphalt batching plant, both the plan and any component can be customized. SDCAD's service is beyond imagination. We look forward to hearing from you.

Contact Us

WeChat ID: + (86) 15244146667